If a country house is designed not only for the periodic arrival of its owners during the summer season, but for their long or even permanent residence in it, then you can not do without a heating system. This issue is always carefully thought out even at the stage of designing a construction or reconstruction, and is taken into account when purchasing ready-made housing.

This question is extremely serious, requiring careful consideration of all the existing conditions: periods of future operation of the building, the climatic zone of the area, the availability of power lines, utilities, structural features of the building, the total estimated cost of the implementation of a project. And yet, most often, homeowners come to the conclusion that the optimal solution will be water system closed heating in a private house.

This publication will discuss basic principles closed system, its differences from the indoor, existing advantages and disadvantages. Attention will be paid to the main elements of such a system with recommendations for their choice, typical wiring diagrams of the heating house building network are given.

Closed-type heating system in a private house - main features

A private house can be heated in different ways.

- For a long time, the main source of heat was one or more stoves (fireplaces), each of which heated a particular section of the building. The disadvantages of this approach are obvious - uneven heating, the need to conduct regular furnaces, monitor the combustion process, etc.

Stove heating is already “yesterday”

Currently, this type of heating is used less and less, and as a rule, when it is absolutely impossible or completely inexpedient to use another, more efficient system.

- System electric heating using convectors or oil radiators - extremely expensive to operate due to the high price of electricity and its high consumption.

True, alternative methods appear, in the form of film infrared elements, but they have not yet gained wide popularity.

- Most owners of private houses also stop at water heating. This is a proven effective system, which, by the way, can work from almost all energy sources - natural gas, liquid or solid fuel, electricity, which determines its full versatility - the only difference is in the type of heating boiler. A well-calculated and correctly installed water heating system provides an even distribution of heat throughout the premises, and can be easily adjusted.

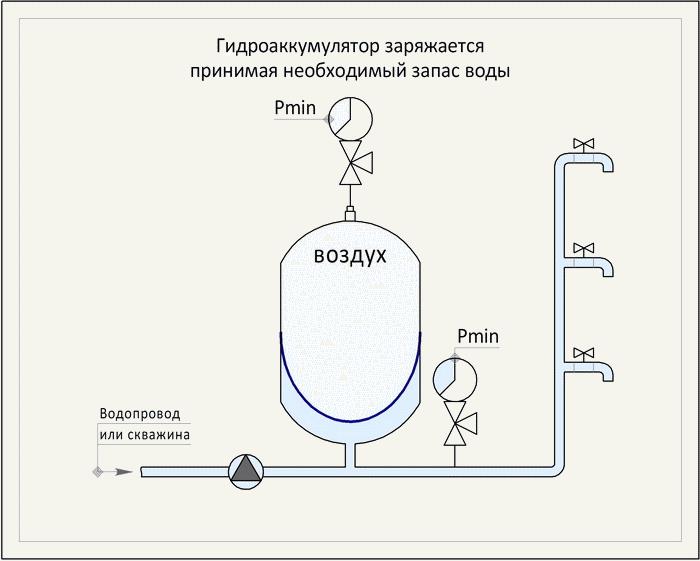

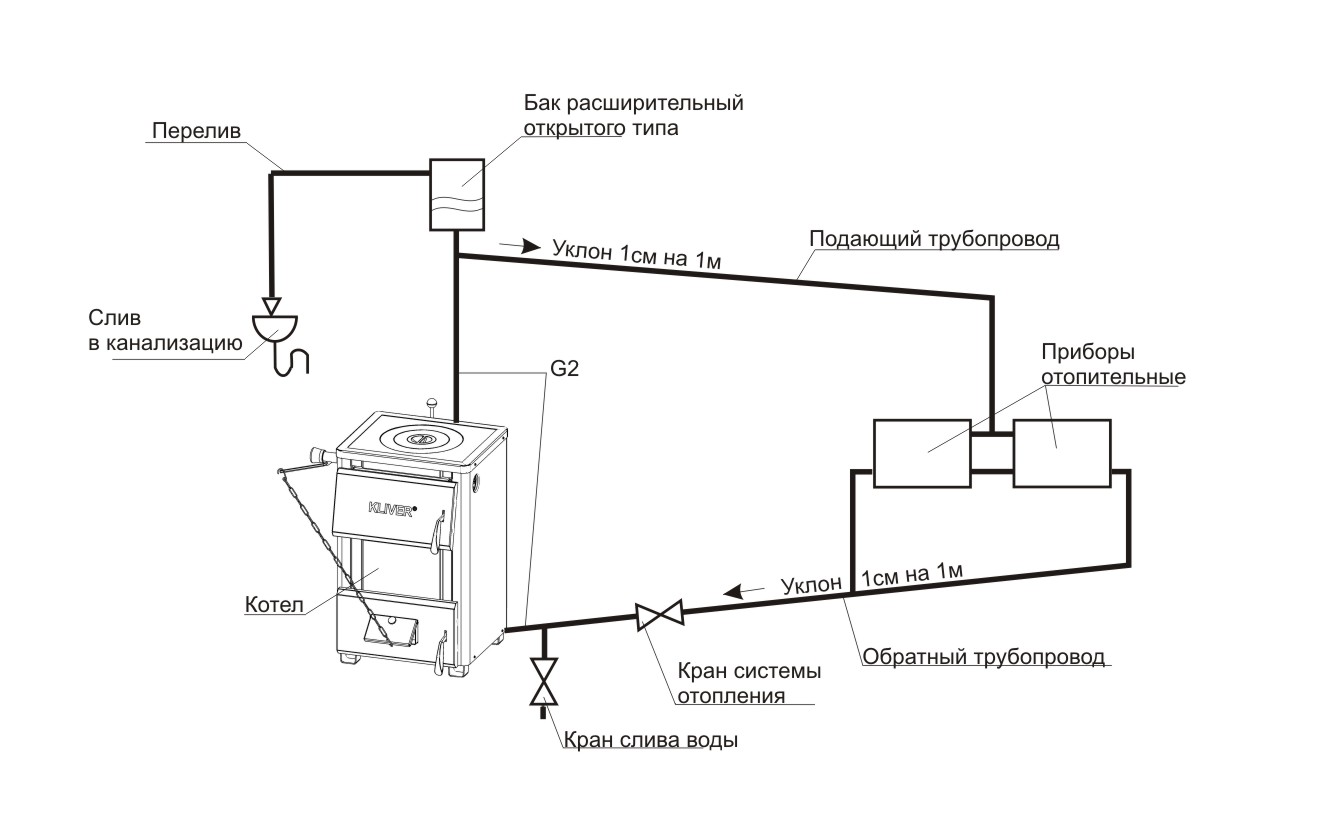

Not so long ago, the main scheme for organizing water heating in a private house was open with the gravitational principle of moving the coolant through pipes and radiators. Compensation for the thermal expansion of water occurred due to the presence of an unpressurized expansion tank, which was installed at the highest point of the entire circuit of the heating system. Of course, it constantly causes the evaporation of water, so there is a need for constant monitoring of its necessary level.

The movement of the coolant through the pipes is ensured in this case by the difference in the density of cold and heated water - a denser cold, as it were, forces the hot forward. To facilitate this process, an artificial slope of the pipes is created along their entire length, otherwise the effect of hydrostatic pressure may occur.

It is quite possible to embed a circulation pump into an open system - this will sharply increase its efficiency. In this case, a valve system is provided so that it is possible to switch from forced circulation to natural and vice versa, if necessary, for example, in case of power outages.

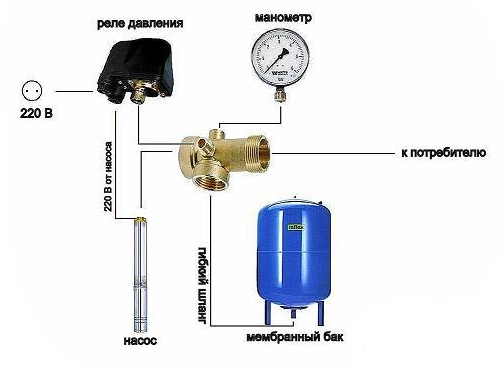

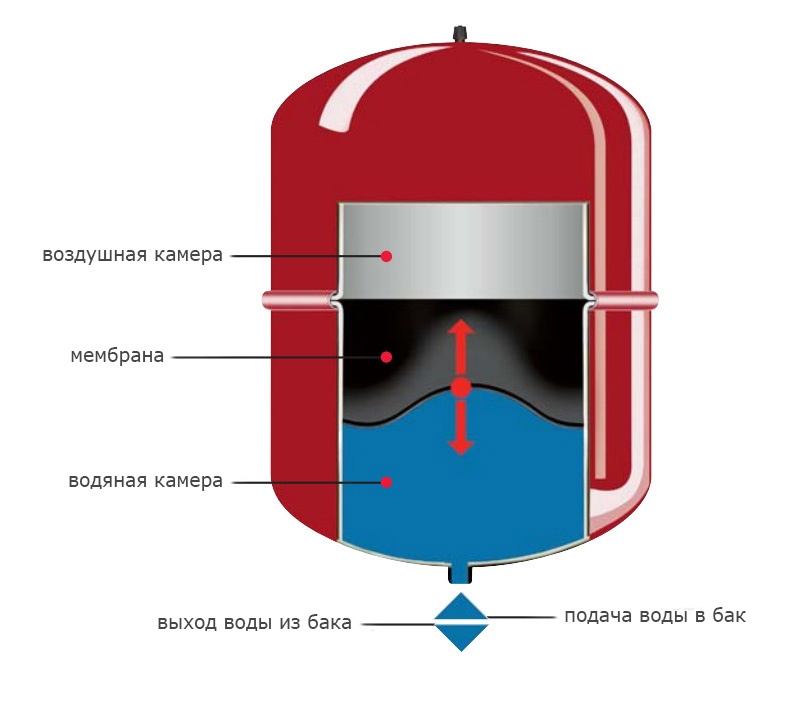

The closed system is arranged in a slightly different way. Instead of an expansion tank, a sealed expansion tank of a membrane or balloon type is installed on the pipe. He perceives all thermal fluctuations in the volume of coolant, supporting closed system one level of pressure.

The main difference between a closed system is the presence of a sealed expansion tank

IN present this the system is the most popular, as it has many significant advantages.

Advantages and disadvantages of a closed heating system

- First of all, the coolant does not evaporate. This gives one important advantage - you can use not only water, but also antifreeze in this capacity. Consequently, the possibility of freezing the system during forced interruptions in its operation, for example, if necessary, leave the house for a long time in the winter, is eliminated.

- The expansion tank can be located almost anywhere in the system. Usually for neg provide a place directly in the boiler room, in the immediate vicinity of the heating device. This provides a compact system. An open expansion tank is often located at the highest point - in an unheated attic, which will require its thermal insulation. In a closed system, such a problem does not exist.

- Forced circulation in a closed system provides much faster heating of rooms from the moment the boiler is started. There are no unnecessary losses of thermal energy in the area of \u200b\u200bexpansion tank.

- The system is flexible - you can adjust the heating temperature in each specific room, selectively disable some parts of the general circuit.

- There is no such significant difference in the temperature of the coolant at the inlet and outlet - and this significantly increases the time of trouble-free operation of the equipment.

- For heating distribution, pipes of much smaller diameter can be used than in an open system with natural circulation without any loss of heating efficiency. And this is a significant simplification of installation work, and a significant savings in material resources.

- The system is tight, and with proper filling and normal operation of the valve system, there simply should not be air in it. This will eliminate the appearance of air congestion in pipelines and radiators. In addition, the lack of access to oxygen contained in the air, does not actively develop corrosion processes.

In a closed heating system, you can include "warm floors"

- The system is highly versatile: in addition to conventional heating radiators, water "warm floors" or convectors hidden in the floor surface can be connected to it. Such a heating system easily connects a domestic water heating circuit - through an indirect heating boiler.

The disadvantages of a closed heating system are few:

- The expansion compensation tank should have a volume larger than with an open system - this is due to the peculiarity of its internal design.

- Mandatory installation required the so-called "security group" - safety valve systems.

- The correct operation of a closed heating system with forced circulation depends on the continuity of power supply. You can, of course, provide, as with the open type, a switch to natural circulation, but this will require a completely different arrangement of pipes, which can reduce some of the main advantages of the system to zero (for example, the use of "warm floors" is completely eliminated). In addition, the heating efficiency will decrease sharply. Therefore, natural circulation, if it can be considered, is only as an "emergency", but most often a closed system is planned and mounted specifically for the use of a circulation pump.

The main elements of a closed heating system

So, the composition of the total closed-type heating system for a private house includes:

- heating device - boiler;

- circulation pump;

- pipe wiring system for heat transfer;

- expansion expansion tank sealed type;

- heating radiators installed in the premises of the house, or other heat transfer devices (“warm floors” or convectors);

- safety group - valve system and air vents;

- necessary shutoff valves;

- in some cases, additional automatic control and management devices that optimize the operation of the system.

Heating boiler

- The most common are gas boilers. If a gas main is drawn to the house or there is a real opportunity to lay it, then most owners prefer in no way an alternative to this method of heating the coolant.

Gas boilers - the best solution if it is possible to install them

Gas boilers are characterized by high efficiency, ease of operation, reliability and efficiency in terms of payment for energy. Their disadvantage is the need to coordinate the installation project with the relevant organizations, since completely special safety requirements are imposed on such a heating system.

The variety of gas boilers is very large - you can choose a floor or wall model, with one or two circuits, simple to install or saturated with electronics, requiring connection to a stationary chimney or equipped with a coaxial exhaust system.

- Electric boilers. They are usually installed in conditions where gas supply to the house for any reason is impossible. Such an installation will not require coordination - the main thing is that the requirements of electrical safety and the compliance of the boiler power with the capabilities of the electric network are met. Such heating devices are distinguished by compactness, simplicity and ease of adjustment.

For heating systems with electric boilers the reputation of “uneconomical” has been firmly established due to the relatively high cost of electricity. This is only partly true - modern electric heaters, thanks to new technologies for heating water, have very high efficiency, and with reliable insulation of houses, they should not burden the budget too much.

In addition to boilers familiar to everyone with heating elements (which are really not very economical), modern developments are actively used.

"Battery" of three electrode boilers

For example, electrode boilers are widely used, in which heating is carried out due to the flow of alternating current directly through the coolant (however, it will require a specially selected chemical composition of the water in the system). Such boilers themselves are inexpensive, but there are certain problems with adjustment.

Induction boiler - unpretentious and very economical

Another option is induction-type boilers in which all metal surfaces of the structure, on which Foucault induction currents are induced, act as heating elements. The efficiency of such installations tends to 100%, and the automation units make it easy to adjust the system to the desired operating mode, ensuring maximum efficiency. So the modern electric type of a closed heating system is a worthy alternative to a gas one, and in many respects it even has advantages.

- Solid fuel boilers cannot be discounted either. In some regions, this will even be the best option for organizing a heating system - for example, in the absence of a gas supply and an unstable power supply.

These heating devices are not at all those old "stoves", but modern installations, the device of which allows minimizing human intervention in their work. So, many long-burning boilers with pyrolysis afterburning are able on one tab of firewood to provide the heating system for 10-15 hours, and in some models this figure reaches even a day. Many boilers are equipped with an electronic control system and operating mode control.

So, if there are no problems in the locality with the preparation of the necessary supplies of firewood or other solid fuel, then this can be the best solution.

- In certain circumstances, a lean owner may consider installing a combined boiler, for example, “firewood - gas”, “firewood - electricity”, “electricity - gas”, thereby ensuring the universality of his heating system.

Whatever boiler is selected, it is necessary to correctly calculate its power. By and large, this should be carried out by a specialist, taking into account the characteristics of a particular house, its heat loss, depending on the number and area of \u200b\u200bwindows and doors, material and wall thickness of the building, climatic conditions of the area and other factors. Far from always, however, the hosts resort to the help of professionals, focusing on simplified calculation schemes.

With some assumption, for the conditions of central Russia, provided that the building is thermally insulated, a value of 1 kW per 10 m² of heated area can be taken if the ceiling height is within 2.5–3 m. So, for a house with a total area of \u200b\u200b150 m², a boiler with a capacity of at least 15 kW is required.

Circulation pump

The main task of this device is to ensure stable circulation of the coolant throughout the heating circuit, including laid pipe sections and radiators. This means that inevitably the problem arises of the correct selection of the necessary pump so that it fully copes with its function. This is determined not at all by the diameter of the pipe for which it is designed, but by the performance indicators and the created water pressure.

1. The first parameter is performance. The pump should be able to pump a certain amount of liquid per unit time, and therefore - to transfer the necessary amount of heat along with the coolant to the premises of the house. How to calculate the required value.

A simplified formula looks like this:

Q \u003d P / (Δᵗ × 1.16)

- Q -required pump capacity;

- P -the total power of the heating system, the simplified calculation of which is mentioned above, in the section on boilers;

- Δᵗ — the temperature difference of the coolant at the inlet and outlet of their system. For closed systems, 20 degrees is usually taken, in the case of radiators. For a warm floor, this value is 5 degrees, and for hidden convectors - 10 .

- 1,16 - an indicator of the heat capacity of water. If another liquid is used, then its heat capacity is easy to find in the directories.

Take the same example, with a house of 150 m² and a boiler of 15 kW, in the heating system of which radiators are used.

G \u003d 150,000 / (20 × 1.16) 646 kg / h

The density of water at a temperature of 80º FROM - 972 kg / m³. So, performance is required:

646 / 972≈ 0.66 m³ / hour

Therefore, the purchased pump must have a capacity not lower than the calculated one.

Calculator for calculating the performance of the circulation pump

The heating system of a private house (as well as water supply) must be functional and reliable. If during the installation any violations were committed or something was not done, then it will not last long, even if it works for some time. One of the main elements in any autonomous system associated with the use of water is an expansion tank for water supply, the selection, installation, installation of which will be discussed in this material.

What is it?

Even the name itself speaks for itself - an expansion tank is needed to expand the entire heating circuit of the house or water pipes through which hot or cold water flows. The fact is that during heating, the fluid increases in volume, and the pipes through which it flows do not change their physical parameters - their elasticity tends to absolute zero. This means that the pressure inside the pipes and the entire installation will increase, which can lead to damage - so-called water hammering occurs, and as a result of them - the destruction of individual installation elements or circuits from the pipes. This applies mainly to the heating system, but also has a full relation to hot water supply.

To avoid water hammer, the engineers decided to include in the system a small tank filled with air, that is, the substance that, unlike water, is compressed. And if the pressure in the pipes increases during the heating of the water, then thanks to this, the tank will increase very slightly.

On a note! Expansion tank It is often installed in other systems, but its purpose is the same - to reduce pressure in pipelines and the risk of air congestion.

Another such tank is sometimes used to create a reserve supply of cold water and ensures the supply of fluid to any place in the system in a matter of minutes. At the same time, the average capacity is about 30 liters.

For the system that provides the house with water, most often used tanks equipped with membranes. This is a relatively small container, inside which there is a diaphragm made of an elastic material and separating the device into two parts - with air and airless, or rather, water. When the water supply system works, the water chamber is filled with liquid and, acting on the membrane, compresses it, reducing the volume of the air part, increasing the pressure in it. As soon as the pressure reaches a certain level, the pump forcing water will stop. And its inclusion occurs when the pressure drops to minimum values.

On a note! The pressure inside the system allows you to track the pressure gauge installed in it.

Such a tank allows for uninterrupted operation of the water supply system and a steady flow of water in any house, even in a multi-storey building.

Types of tanks

Expansion tanks are of two types - closed and open. They differ from each other by design features.

Table. Types of expansion tanks.

| A type | Description |

|---|---|

| This is a tank that has just a membrane separation between the compartments - water and air. The diaphragm in it is heat-resistant and avoids corrosive activity. Such a tank is sealed, looks like a small balloon or ball of metal. This element of the system serves for a long time, and if the membrane is damaged, it is easy to replace it with a new one. In addition, a pressure gauge and a safety valve must be installed for an expansion tank of this type - all together they form a security system. |

| Such a tank is a tank, at the bottom of which there is a threaded connector, which allows you to combine the device with the system. It is necessary to install this design in the highest part of the heating system. It is used extremely rarely, since it has a lot of disadvantages - this is an increase in the risk of corrosion in the pipes, and fairly decent dimensions, and a quick failure at critical pressure indicators. The liquid level indicators in such a tank directly depend on how much water is in the heating circuit. |

Membrane tanks, in turn, are divided into two types - with a replaceable diaphragm and with a stationary one. The replaceable membrane speaks for itself - if necessary, it can be easily changed by removing it through a flange secured with several bolts. An expansion tank of this type lasts as long as possible, and in the shape of the body it can be either vertical or horizontal, which makes it possible to select a container for a specific room.

Attention! In large expansion vessels, the membrane is additionally fixed with a nipple.

In containers with a stationary membrane, this part cannot be replaced - it is tightly attached to the walls of the housing. In case of failure of the unit, it is completely changed. By the way, water in such an installation, unlike the previous type, is in contact with the metal of the tank, as a result of which a corrosion process occurs on its inner surface. Installation also happens both vertically and horizontally oriented.

Expansion tanks are not only mounted, but also floor. They can also have a flat shape, differ in color: blue ones are for cold water, red ones are for hot water.

Popular models

Now on the market there is a huge assortment of different expansion tanks from various manufacturers. Models differ from each other in quality, size, shape and even color, although by the principle of operation they are similar to each other. To pick up a tank for a specific water supply system will not be labor. You should pay attention to the tank models from the following companies - Russian "Dzhileks" and Italian Elbi, Aquasystem, as well as Refix (Reflex), Zilmet.

The advantages of Jileks tanks are the complete absence of the risk of air congestion in the system and the absence of contact of water with air, which eliminates the evaporation of liquid and rust does not damage the pipes. The brand produces tanks of various volumes - from 6 to 700 liters. The lack of tanks is that removable membranes are only available for installations with a volume of over 24 liters. By the way, the diaphragm is made of high-quality EPDM - ethylene-propylene-diene-rubber. Jilex tanks are economical, durable, inexpensive, but reliable and can have various shapes.

Elbi tanks have all the necessary documents, including a certificate of conformity and a sanitary and epidemiological certificate, which allows you to safely use them in residential buildings. There are vertical, horizontal, as well as for sanitary water. Vertical tanks belong to the AS / AC series and have interchangeable diaphragms, can be of different sizes - from 5 to 25 liters - and are used in domestic water supply systems, as well as in irrigation systems and other installations that do not need a powerful water pressure. The membranes inside the tanks are made of EPDM, the operating temperature ranges from -10 to +99 degrees. The tank is protected from corrosion by resistant paint.

Elbi tanks of horizontal installation method belong to the AFH series and have replaceable membranes. They have more capacity than the previous series - from 25 to 100 liters of water. Such installations can already be used in small industries. Tanks are made of durable steel and have a special platform for mounting the pump.

Refix tanks are suitable for use in both technical and drinking water supply systems and are excellent accumulators. All parts in contact with water are protected from rust, and the liquid is perfectly stored inside rubber pears. Models DD, DE are designed for use in water conservation, are used in drinking water supply systems, ideal for use in environments with a high level of rust formation. The DE series tanks have a pear, which is interchangeable only on models with a volume of over 50 liters. The models of the HW series, designed for individual water supply systems, also have legs for installation on the floor and a place for mounting the pump.

The international company Zilmet has been holding high positions in the equipment market for more than 50 years, and in Europe it is considered the largest manufacturer of expansion tanks. Their Hydro-PRO devices are used to work with any water in various types of installations. The equipment is made of carbon strong and high-quality steel, and special MIG welding is also used in the production, due to which it is possible to avoid damage to butyl rubber membranes. Inside the tanks are coated with high-strength powder resin, which prevents the occurrence of rust during prolonged contact with moisture. Operating temperature range - from -10 to +99 degrees.

Aquasystem tanks have replaceable membranes and come in various volumes - from 8 to 50 liters. The maximum pressure of the coolant is 0.5 MPa, and air - 0.15 MPa. The operating temperature range of the equipment varies from -10 degrees to +110. Tanks are made of black steel, painted with powder paint.

Attention! Do not chase the cheapness! As you know, avaricious pays twice. The fact is that the use of low-quality equipment can lead to serious damage not only to the expansion tank, but also to the system itself, and repair will cost much more than buying high-quality equipment right away.

Regarding the quality of the equipment, special attention should be paid to the rubber from which the diaphragm is made. Good rubber is not only a guarantee of a long service life of the equipment, but also the safety of those who will use water from a water supply system equipped with a tank.

Accumulator selection

When choosing an expansion tank, you should pay attention to its characteristics, the materials from which it is made. The material of which the pear or diaphragm is made, its strength and quality, compliance with all hygiene and sanitary standards, permissible temperature of use, are necessarily evaluated. From the right choice in accordance with the operating conditions, the longevity of the work will depend.

An important point when choosing equipment is the correct selection of the required capacity. This will prevent the number of starts of the pump in the system, which will extend its service life. You can calculate the correct volume for a cold water supply system using the formula:

Vt \u003d 16.5 * (Qmax / a) * ((Pmax * Pmin) / ((Pmax - Pmin) * Pprec)),

- Qmax is the maximum water consumption (l / min.);

- a - the optimal frequency of turning on the equipment for 1 hour (varies from 10 to 15 and is indicated in the pump passport);

- Pmax and Pmin - values \u200b\u200b(measured in bars) that show the pump on and off pressures (pressure switch settings);

- Pprec (bar) - an indicator of the initial pressure in the cavity with air inside the expansion tank (should not be greater than the indicator Pmin; on the contrary, it is set 0.5 less than Pmin).

Note! When calculating by this formula, 1. is added to all values. And the value of the volume of the capacitance Vt obtained by the formula is always rounded up.

For hot water systems, the volume is calculated differently:

V \u003d 0.0221 * C / (1 - ((Pi + 1) / (Pf + 1)),

- C is the total amount of water in the water heating system;

- 0,0221 - an indicator of thermal expansion, in the range of 10-60 degrees equal to this figure;

- Pi is an indicator of the pressure of the preliminary injection of the expansion tank;

- Pf - pressure indicator during bleeding of the safety valve.

The amount of water used, in turn, is affected by the number of people living in the house, the number of points of water use (taps, washing machines etc.), the ability to include several such points at once.

Attention! If you use a tank of the wrong size (with underestimated rates), then soon due to a heavy load it will start to leak. Fortunately, with an increase in the number of people living in the house, and hence the load on the equipment, you can install an additional tank without removing the already installed one.

Expansion tank volume calculator for heating system

Designing a modern autonomous heat supply for residential buildings, apartments and industrial facilities is a serious work that requires the correct execution of calculations and coordination of the parameters of the equipment being installed. For trouble-free functioning of the heating circuit under load, it is important to choose the right expander and professionally install the expansion tank of the heating system. Consider the design nuances, the specifics of the connection and service of the device, compensating for the increase in the volume of coolant.

Why do I need to install an expansion tank in the heating system

The physical properties of a fluid that increases in volume with increasing temperature are the cause of pressure surges that occur in a closed heating circuit. In this regard, the connection of the expansion tank to the heating system is relevant, as it allows to solve a number of serious problems:

- compensate for the thermal expansion of the fluid in the heating pipes. The working capacity of the tank takes the excess water that appears during the volume expansion of the liquid. The device does not allow increasing pressure to damage the boiler and ensures the integrity of the pipelines;

- smooth out water hammer associated with the periodic switching on and off of the circulation pump. In case of fluctuations in the room temperature, the equipment supplying the coolant cyclically functions, causing short-term pressure surges.

The working tank of the expander, being a kind of buffer for the heating circuit, provides:

- increased service life of heating elements;

- stabilizes the effect on equipment of excessive pressure and temperature;

- increased reliability and operational safety of nodes.

The above arguments confirm that the installation of an expansion tank in the heating system is a must.

Expander Volume Determination

Capacity or, as experts say, the useful space of the expander is a priority parameter of the device. Its value should with a margin exceed the maximum amount of thermal carrier, which as a result of expansion fills the tank. This is due to the fact that with an increase in the intensity of the boiler, the volume of liquid located in the pipelines increases. It fills the damper tank, receiving an increased amount of coolant.

The capacity of the expander is affected by the type of fluid used. To perform the calculation, the following parameters are used:

- the volume of the tank is 15% of the total amount of water filling the heating circuit;

- capacity increases to 20% when filling the heat supply system with antifreeze.

The algorithm for calculating the capacity of the expansion tank provides for the determination of the total amount of working fluid. It is calculated by summing the volumes of individual structural elements:

- heating boiler. Information about capacity contains the technical passport of the unit;

- highways. The volume of pipes is determined by multiplying the internal cross-sectional area by length;

- radiators. In the absence of data in the passport, it is possible to experimentally calculate the volume by filling the battery with water.

Having obtained, by calculation, the volume of the circuit, it remains to multiply the obtained value by a factor of 0.15 for water or 0.2 for antifreeze.

For example, with a capacity of highways and devices of 60 liters, a damping tank of the following volume will be required:

- 60 x 0.15 \u003d 9 liters - when using water;

- 60 x 0.2 \u003d 12 liters - when filled with antifreeze.

The above algorithm allows you to quickly make calculations to determine the main operating characteristics of the expander.

Where they put the expansion tank in the heating system

Depending on the design features of the heating, the location of the damper tank changes:

- in an open type design, it is installed at the most elevated point, which is usually located in a room located under the roof or in the ceiling area of \u200b\u200bthe boiler room. An open system is a vessel of complex configuration in which characteristic convection flows arise. Placing the boiler at the upper point contributes to the accelerated rise of the heated coolant, followed by gravity flow to the heating devices through pipes. In addition, the upper arrangement provides unobstructed lifting of the resulting air bubbles;

- for closed heating The optimal installation area for the tank is a straight section in front of the pump, which provides forced circulation. The absence of turbulence in the straight section of the line and the constant flow rate of the liquid create favorable conditions that allow the tank to compensate for hydraulic shocks and dampen the thermal expansion of the carrier. In this case, the air formed during heating of the liquid can be removed without hindrance using existing air taps.

When determining the installation location of the expander, pay attention to the following points:

- the proximity of the tank to the boiler room or furnace room, facilitating control over the operation of the device;

- free access to the damper tank, allowing for unit maintenance;

- the presence of a gap between the body and the wall that facilitates the visual inspection;

- reliability of fixing the tank with the coolant, which should be independently mounted without transferring the load on the supply lines.

Proper placement of the expansion vessel will ensure proper operation and ease of maintenance.

What are the expansion tanks depending on the heating system

The design of the damper tank depends on the type of heating circuit:

- in a system with natural circulation, expansion devices of an open type are used, allowing, if necessary, to fill the liquid. Open tanks do not need shutoff valves, sealed lids and rubber membranes. Liquid is added by opening the tap of the water main or manually using a bucket;

- in a closed heating circuit with forced circulation, closed-type expanders are used. They are made in the form of a sealed reservoir, divided by a rubber membrane into two parts. One is inert gas or air. In the other, a coolant, which, with an increase in volume, deforms rubber, reducing the volume of the chamber with air, and thus compensates for load differences.

In closed systems, the following types of tanks are used:

- flange equipped with a replaceable balloon type membrane;

- flangeless with a stationary diaphragm membrane.

More modern closed-type constructions are gradually replacing open heat supply systems, which are more susceptible to corrosion, require constant monitoring of the liquid level and regular topping up. The final decision on the choice of the type of damper unit is dictated by the design of the installed heating.

Open expansion tank

For decades, the damping capacities of the heating circuits have been widely used in natural circulation systems. They made it possible to replenish the supply of water with small leaks or evaporation of the coolant, and also ensured the removal of air bubbles from the heating circuit.

Design

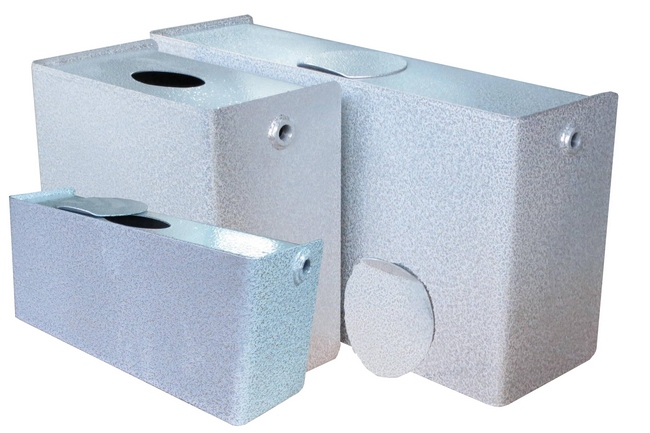

Structurally, the open expander is a welded vessel in communication with the atmosphere, made in the form of:

- cylinder;

- parallelepiped.

The following materials are used for manufacturing:

- sheet steel;

- polymeric materials.

The tank is equipped with the following elements:

- a cover that protects the thermal medium from dirt and provides access during maintenance;

- strong bracket that allows you to securely fix the case to the wall of the room;

- pipes necessary for connecting heating circuit lines, as well as water supply and overflow pipes;

- drain valve, allowing during the maintenance and repair work to drain the coolant.

Due to the simplicity of the design, an open type expander is not difficult to manufacture independently.

Advantages and disadvantages

The main advantages of an open damper tank:

- the possibility of self-manufacturing;

- simplicity of design;

- low cost;

- air exhaust efficiency;

- accelerated pressure relief.

Along with the advantages, the open design has a number of serious disadvantages:

- the need for thermal insulation of an expander located in an unheated room;

- contact of the heat carrier with the atmosphere, which is the cause of corrosion of metal elements;

- the need for regular topping up of the liquid into the container associated with its constant evaporation;

- special installation requirements for the installation of additional lines.

Design weaknesses limit the widespread use of open tanks.

Installation of an expansion tank in an open heating system

When deciding how to connect an expansion tank to an open heating system, one should be guided by the recommendations of a previously developed project and instructions. In this case, special attention must be paid to compliance with the following requirements:

- installation of a damper on the highest elevated part of the heating main;

- ensuring reliable fastening of the tank, the mass of which increases when filled with water;

- thorough insulation of the housing surface, which reduces heat loss and protects the liquid from freezing;

- maintaining the operational parameters of the circuit by adding water, the level of which must be regularly monitored.

Installation activities include the following operations:

- installation of a control pipe at the level of the minimum coolant volume;

- installation of the overflow line, carrying out the discharge at the maximum mark;

- connecting the supply line to make up for losses.

Activities for connecting the tank do not require special training and can be carried out independently.

Closed expansion tank

Closed damper tanks equipped with an elastic diaphragm or water chamber are used in forced-circulation heat supply circuits. They provide reliable compensation for pressure surges and dampen the increase in coolant volume. Thanks to a set of advantages, hermetic expanders compare favorably with similar open-type units.

Membraneless

Expansion containers, in the design of which there is no membrane, were widely used until the appearance of high-quality rubber membranes with an increased service life and strength. They functioned without a membrane, however, they needed to connect a cylinder with compressed air or a compressor supplying air in the required quantity.

Device Features:

- the absence of mechanical separation of the tank capacity, resulting in direct contact of the coolant with the gas;

- the need to maintain operating pressure with a gas cylinder or compressor;

- the ability to operate a membraneless tank only with automatic control of operation and continuous gas supply.

Membraneless tanks are significantly inferior in performance to membrane devices.

Membrane

The design features of the membrane expander provide for the separation of the coolant and the gas medium by an elastic membrane having a different shape:

- hemispherical (dish-shaped). The membrane is a stationary element and, under the influence of pressure, takes a spherical shape;

- balloon (pear-shaped). The removable membrane is attached to the flange on the vessel body and under load tends to repeat its shape.

A device with a disk diaphragm is characterized by the presence of the following elements:

- a vertically arranged steel case representing a sealed capsule consisting of two parts;

- a rubber membrane fixedly mounted between the components of the steel capsule;

- a pipe located in the lower part of the tank, and intended for connection to heating lines;

- a nipple located at the top of the tank and allowing air to be pumped into the tank.

With increasing temperature, the excess coolant enters the tank between the membrane and the housing, compressing the air. When the temperature created by the boiler decreases, the volume of water decreases. It is squeezed out by compressed air located in the upper part of the tank. The sealed design of the damping tank allows you to change the air pressure if necessary by opening the nipple or by pumping.

Tanks equipped with a pear-shaped balloon membrane are made for closed systems in vertical and horizontal versions. The design of the device consists of the following parts:

- stamped containers with a flange for mounting the balloon membrane;

- a rubber chamber for water inserted into the housing and hermetically connected to the flange;

- a connecting pipe required to connect the damping device to the pipes;

- bottom valve designed to maintain air pressure.

The design feature of the tank is that the coolant does not come in contact with the metal surface, but fills a rubber balloon. This allows you to protect the steel casing from corrosion processes and extend its life. Unlike diaphragm containers, the ability to replace a rubber bottle is a great convenience.

Advantages and disadvantages

Advantages of membrane devices:

- compact dimensions;

- minimum heat loss;

- lack of need for external thermal insulation;

- the possibility of functioning without recharge;

- complete tightness;

- work with increased pressure;

- increased reliability;

- operational safety;

- lack of air jams.

The disadvantages include:

- the need to control working pressure;

- the need for periodic pumping of air;

- increased cost.

Devices are widely used due to numerous advantages.

Installation of an expansion tank in a closed heating system

Installation of a damper tank installed in a closed heating circuit is a critical operation that requires special training. However, having the skills to perform plumbing, you can independently install the device, observing the following recommendations:

- install the expander only in the reverse circuit (from the water supply side to the boiler), choosing any convenient place;

- check the pressure in the tank, which should be 0.2 atmospheres less pressure liquids;

- mount the tank in a room with a positive temperature, placing it near the boiler;

- securely attach the container to the surface of the wall, since when filled with liquid, its mass will increase;

- provide access to the air nipple in order to adjust the pressure in the chamber;

- fix the device so that it does not absorb the load from the mass of pipes with liquid;

- connect a tee and shutoff valves, allowing you to disconnect the tank from the heating pipes;

- make the upper pipe supply, which ensures the functioning of the device when the integrity of the membrane is violated.

How to properly use expanders

Measures for the operation of the damper tank include the following maintenance rules:

- visual inspection of external damage associated with corrosion and mechanical stress;

- pressure control of the airspace of the tank, which must comply with the passport data;

- checking the integrity of the rubber membrane, which must be replaced if damaged;

- drainage of water from the damper tank during the conservation of heating for a long period.

Frequency of control - at least twice during the year.

Conclusion

The recommendations given in the article material will help to choose the damping capacity correctly and calculate its volume. Knowing how to put expansion tank for heating, you can ensure the safety, reliability and durability of the heating structure with natural or forced circulation of the coolant.

The best material for car trim

Principles of hardening the body

Do-it-yourself compressor - with minimal scrap costs

Which is better: do-it-yourself or factory-made compressor for painting a car

Causes of fuel pump malfunctions