The situation when the engine stalls and does not pump the gas pump on the VAZ 2110 can put a novice motorist in a difficult position. Especially if he is new to with fuel supply system and its configuration, as well as with a list of equipment that ensures the regular functioning of this system.

The lack of fuel at the outlet of the pump is not yet a fact of its failure.

The gas pump on the VAZ 2110 does not pump, not only because of its breakdown, since there may be several reasons for this behavior.

Now the main thing is not to panic, and first of all remember when the car was last refueled. The indicator indicator on the dashboard still does not mean anything. The level sensor in the tank can “stick”, like the arrow on the indicator (see).

If the car is already more than 3 years old and it has measured more than 100 thousand mileage with its tires, then any surprises in terms of failures can be expected from its systems and equipment.

Procedure for testing the causes of failure

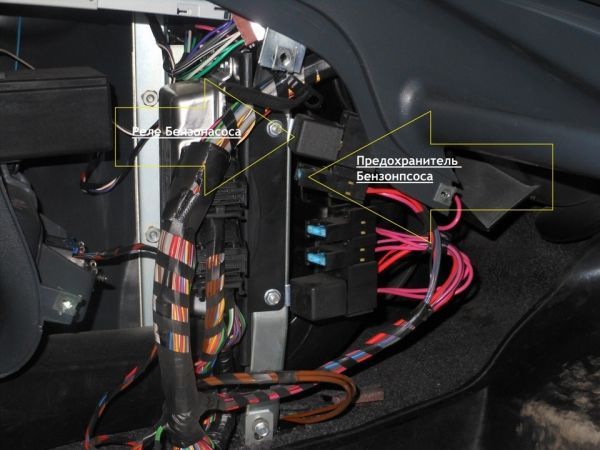

The next suspected is the electrical wiring of the pump power. In the power circuit from the on-board system of the car to the electric motor of the pump is a fuse and relay insert. They are installed not on the main fuse board, but on the additional one, which is located on the “top ten” under the front panel to the right of the steering unit.

If you look at this additional unit, the relay and the safety insert of the pump motor will be on the left (there are only three sets of relays and fuses).

Checking the wiring does not require special knowledge and does not take much time. But if everything is normal with the power supply, further verification requires dismantling the pump casing.

Reasons inherent in the pump

A pump can not supply fuel completely for only two reasons:

- burnout of the motor windings;

- to such an extent that the remaining cross-sectional diameter of their holes is not enough for the pump to draw fuel from the tank.

Both the first and second reasons are equally probable, they are interconnected. When filters are dirty, when they have not only been changed for a long time, but have not been cleaned, their throughput decreases sharply.

To this we can add the processes of sedimentation on the walls of the fuel line of various impurities and additives, which are found in our gasoline in large quantities. As a result, the load on the gas pump increases, it runs to the limit and starts to overheat.

Cools down The fuel pump circulates the fuel through it, since it has a lower temperature than water and is an excellent cooler. But this definition is true only for high-quality gasoline (a rarity in our time). Consequently, substandard gasoline cannot sufficiently cool the pump working with overloads and the windings of its electric motor burn out.

In order not to immediately proceed with the analysis of the gasoline pump, you must make sure that the level is sufficient fuel line sectionlaid from the inlet to the gas tank.

Before starting any work related to testing or repairing fuel equipment, first of all, it is necessary to relieve pressure in the line. To do this, the fuse is removed from the power supply circuit of the pump, and the engine is given time to generate gasoline residues, after which it stalls on its own.

In the evening I drove into the garage, but in the morning I could not start it. I usually turn on the ignition, at the same time I hear a click of the relay and a buzzing pump and somewhere through 3-5 seconds, a click of the relay is heard again and the pump stops and I turn the key to the end, the starter works but the engine does not start because there is no pressure in the power system, the pump does not pump.

I am looking for the cause of the failure of the fuel pump by checking the fuse, which is located

Under the sidewall in the depths are fuse box, relay and computer.

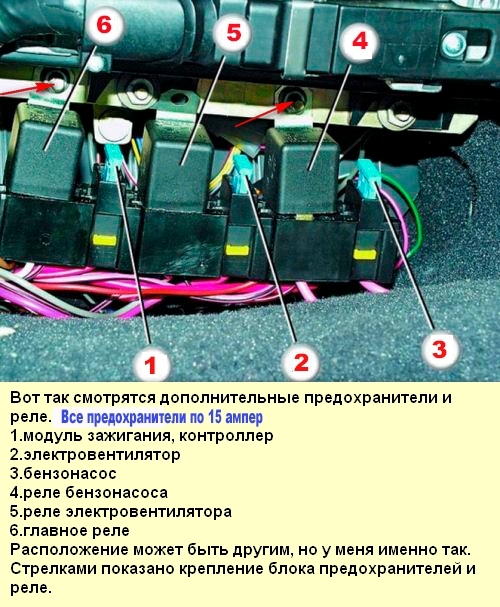

Relay and fuse box enlarged

First, I checked the fuse at number 3, took it out of the socket, examined the condition of the contacts and checked the integrity with the device, the fuse turned out to be intact (by the way, 15 amp)

this did not help, then checked the relay under number 4. To do this, unscrew the nuts indicated by the arrows in order to remove the relay and put in a known good condition. Where to get a working relay? Can be removed for the duration of the test in the relay mounting block " high beam“it’s exactly the same as the fuel pump relay. It didn’t help, I took off the back seat under which the gas tank with the submersible pump is located.

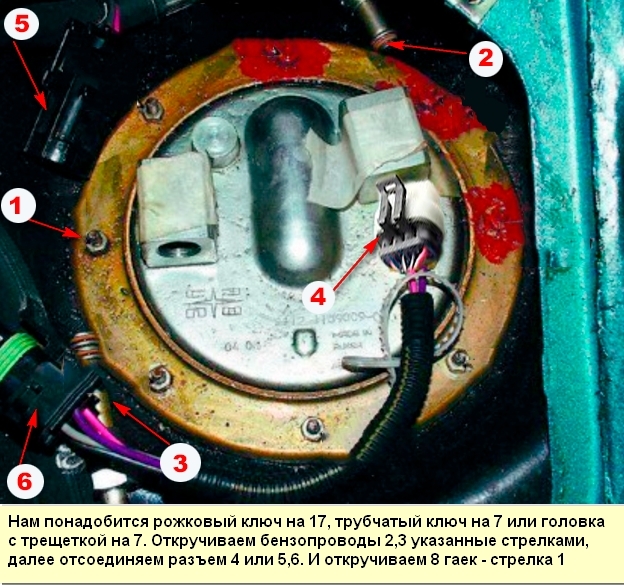

Before performing the above steps, I checked the power circuit (+)(-) those. the mass of the gas pump on the connector under number 5 the device can and the test lamp the result is positive, checked the integrity of the circuit on the pigtail on the connectors under numbers 4.6

It may happen that there is no power circuit ( + ) or ( - ) on the connector under number 5. If ( - ) i.e. the mass does not come to the connector, you need to check the connection with the body. My power circuits rang.

The place of connection of the mass is inaccessible, to get you need to disassemble the upper and lower lining of the floor tunnel.

I checked the power circuits come up to the connector under number 4, and the gas pump does not work, then performed the above actions as shown in the figure, removed the fuel module with the gas pump from the fuel tank. He took off the clamping ring and gasket

He gently pulled the fuel module out of the tank slightly, tilting it to the right side door of the passenger compartment so as not to bend the leash of the fuel gauge sensor float (FLS)

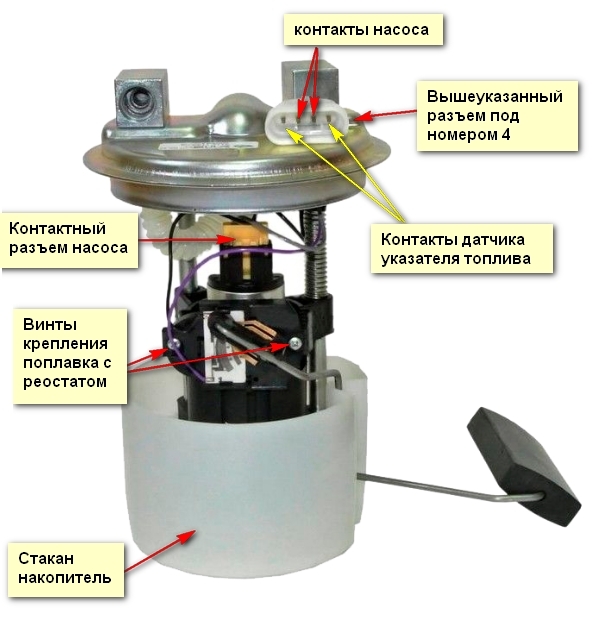

Dismantled the fuel module. Separately checked the pump directly from the battery. The pump is running. I checked the connectors and found the cause of the failure, it turns out that the positive contact of the connector (in the form of a pin) from the bottom under the casing is slightly burnt. I cleaned the contact (in the form of a pin) of the connector, but could not make the other side of the connector.

The VAZ 2110 regular fuel pump is one of the main components of the vehicle fuel supply system. Its main purpose is to ensure the correct transportation of gasoline to the distribution or injection element (that is, to the injector or carburetor) under the created pressure. In the fuel system, dozens distinguish between mechanical type gas pumps and electric pumps.

The pump for fuel supply of the mechanical principle of operation, its parameters and design features

A mechanical fuel pump is mounted on dozens with carburetor motors. It is driven by the camshaft of the power plant, on the block of which it is installed. Structurally, it is classified as a piston type product and its elements include:

- a housing element comprising 2 adjacent compartments and top mount covers;

- a diaphragm located between the body parts;

- reverse spring;

- shock associated with a rigid diaphragm;

- a fuel discharge and suction valve located in the upper segment of the fuel pump;

- mechanical drive;

- filter mesh.

It was previously established that the VAZ fuel pump of the tenth model, the price of which is relatively reasonable, is driven by an eccentric of the engine camshaft. With the circular motion of the eccentric, the lower movement of the diaphragm and the rod is observed, with overcoming the influence of the compression force of the spring.

In this case, the freed space expands, and the fuel fills the discharged plane by entering through the start valve, the discharge element being in the closed state. The diaphragm, consisting of 2 membrane components with gaskets, is the main functional component of the pump. It is connected to a rod connected directly to the elements of the mechanical drive mechanism.

The difference in the parameters of the fuel pump is related to the pressure value and the dimensions of the body part. You should pay attention to the Bosch fuel pump, in which the fuel pressure is in the range of 2.8-3.8 Bar. Product parameters do not always depend on the radius of the hull, here, as a rule, the determining indicator is the length. These dimensions are different, among the copies there are spare parts of 65, 90 or 105 mm. Additionally, these components of the fuel supply system differ in the disposition of split chips.

The ability of an element to perform its functions with a low fuel content in a gas tank depends on the length of the fuel pump.

Electric type fuel pump

Gasoline pump for VAZ 2110 electric type injector is installed in cars with an adjustable injection system. The tens fuel pump is located in the fuel line system in the vehicle’s gas tank. Such a dislocation of the element greatly reduces the possibility of fuel loss due to the use of the circuit without the participation of pipelines that operate on the absorption of fuel.

This element of the fuel supply system includes:

- a pump whose body is made of metal;

- fuel level sensor;

- fuel intake component;

- filter mesh;

- check and pressure reducing valves.

The valve of the inverse principle of action stops the fuel distribution complex when the power plant is stopped. The pressure reducing element controls pressure by acting as a bypass valve.

Designs of gasoline pumps are:

- roller type;

- gear type;

- centrifugal type.

An electric-type roller pump draws in fuel and drives it off due to the functionality of the rotor element and the movement of special-purpose rollers. A gear electric pump sucks in fuel and drives it through and is pumped by moving the internal gears relative to the stator element, which plays the role of the outer gear. When the rotor of the rotary type moves, the lateral tooth elements create a chamber in their segments that changes the degree of rarefaction, with the help of which the effect of suction and fuel intake is created.

At the same time, the centrifugal type fuel pump is mounted directly in the fuel line. Such elements make it possible to ensure an even supply of fuel and operate almost silently. They have one significant feature - the limit on pressure parameters and functionality.

The choice of pump for supplying fuel to the VAZ 2110

Despite the reliability of the element, the fuel pump sometimes comes into malfunction. Typically, the defect is the failure of the electric pump brushes. The fuel pump is selected according to the following criteria: reliability and noiseless operation, because the quieter the pump operates, the more comfortable it is to use.

When choosing a fuel pump, the purchase of the same product with the same item number is required. Often, motorists among the many analogues distinguish the Bosch fuel pump, which is used on 1.6-liter cars and is equipped with a fuel level pressure regulator.

VAZ 2110 gasoline pump which acts as a gasoline supercharger, it is unlikely to be able to move independently without this small, but very important unit. We must say right away that the “tens” carburetor gas pump is mechanical, and the VAZ 2110 injector has an electric gas pump. Today we’ll talk in detail about both.

So, mechanical gas pump for a VAZ 2110 carburetor engine installed between the valve cover and the ignition distributor, in the engine compartment. Actually this arrangement allows you to get a reciprocating moment from the shaft, which comes from the camshaft to the ignition distributor. Thanks to the eccentric on this shaft, movements through the rod are transmitted to the fuel pump lever. The lever itself, in a reciprocating motion, draws in fuel through a membrane. By the way, this pump, like all pumps starting with the VAZ-2101 model, has a manual fuel pumping lever. This is quite convenient, because it allows you to quickly check the operability of the mechanism with literally bare hands. Photo of the mechanical VAZ 2110 pump Further.

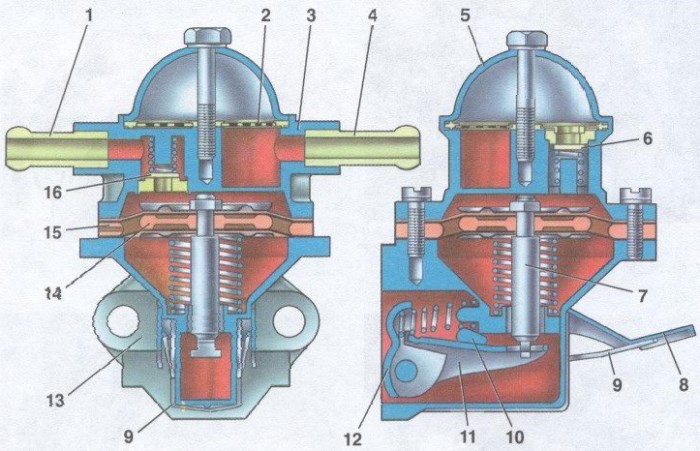

This is how a mechanical pump looks in section, we look at the schematic drawing.

Mechanical fuel pump VAZ-2110 consists of the following elements -

- 1 - discharge pipe

- 2 - filter

- 3 - case

- 4 - suction pipe

- 5 - gasoline pump cover

- 6 - suction valve

- 7 - stock

- 8 - lever for manual pumping of fuel

- 9 - spring

- 10 - cam

- 11 - balancer

- 12 - lever mechanical pumping fuel

- 13 - the bottom cover of the fuel pump

- 14 - an internal remote laying

- 15 - outdoor remote strip

- 16 - discharge valve

Removal and installation of a mechanical pump VAZ 2110 does not cause big difficulties. It is enough to remove the air filter, loosen the clamps of the incoming and outgoing fuel pipes, remove these hoses, then unscrew the two nuts securing the pump itself and you can remove the mechanism from the two studs on which the fuel pump hangs. When installing, it is advisable to replace the gaskets that are on the insulating insert.

VAZ 2110 fuel pump injector

Electric fuel pump injector “tens” is installed directly in the gas tank. Removing and replacing this unit also does not cause problems for the owners of the VAZ 2110. It is enough to raise the rear seat sofa, unscrew the hatch and the fuel lines ... the main thing is not to forget to relieve pressure in the system.

The injection fuel system itself differs from the carburetor version in the method of supplying fuel. If the carburetor engine sucks the fuel on its own from the carburetor, then in the injection motor fuel is injected under pressure through the nozzles. Therefore, the task of the electric pump in the tank is to constantly maintain high pressure throughout the system. The pump turns on and off automatically (using a relay), responding to commands from pressure sensors. Actually, the pump itself looks something like the photo below.

Determine is the electric pump OK? in your car, you can pretty simple. Turn on the ignition (but do not start the engine), and you will hear a characteristic buzzing of an electric pump in the tank, so it pumps up the necessary pressure. If this buzz is absent and the engine does not start, then most likely the pump is faulty. Either the pump relay, which is located in the passenger compartment under the center console of the panel, usually next to the passenger’s feet, is faulty.

It often happens that the pump is not able to create the necessary pressure, although it buzzes, then it also needs to be changed. The VAZ 2110 injector pump is very sensitive to various debris, so be sure to periodically change the fuel filter.

Replacing a gas pump on a VAZ 2110 injector

A very useful video of removing the fuel pump on the “top ten”.

To remove the electric fuel pump, do the following -

- 1 - reduce the pressure in the fuel system

- 2 - remove the hatch under the rear seat

- 3 - disconnect in turn 2 fuel supply hoses

- 4 - unscrew 8 nuts around the circumference of the ring and take it out

- 5 - we take out the pump block from the fuel tank without damaging the lever of the fuel level indicator sensor

- 6 - remove the rubber sealing ring

Do not forget that when installing a new electric VAZ 2110 injector gas pump, the installation arrow on the cover of the electric pump should show the direction to the rear of the car. In addition, when installing the fuel hoses, consider the direction of the arrows.

The best material for car trim

Principles of hardening the body

Do-it-yourself compressor - with minimal scrap costs

Which is better: do-it-yourself or factory-made compressor for painting a car

Causes of fuel pump malfunctions