A conventional DIY air compressor for painting a car body is a high-pressure supercharger assembled on the basis of a car chamber that has served its life. It will play the role of a receiver (a vessel containing a certain gas). In our case, there will be air inside the receiver. A home-made receiver from a car camera is a good option for a small amount of work.

Materials and Tools

To build a compressor for painting a car, you need the following things:

- car pump and manometer;

- car camera;

- set of elements for repairing rubber;

- nipple from an unnecessary camera;

- set of tools.

First you need to find an unnecessary car camera that replaces the receiver. It is important that it be free of punctures, as there is always pressure in the receiver. Be sure to take care of the supercharger. A simple home-made paint compressor can be equipped with a conventional car pump with a pressure gauge that will play the role of a supercharger.

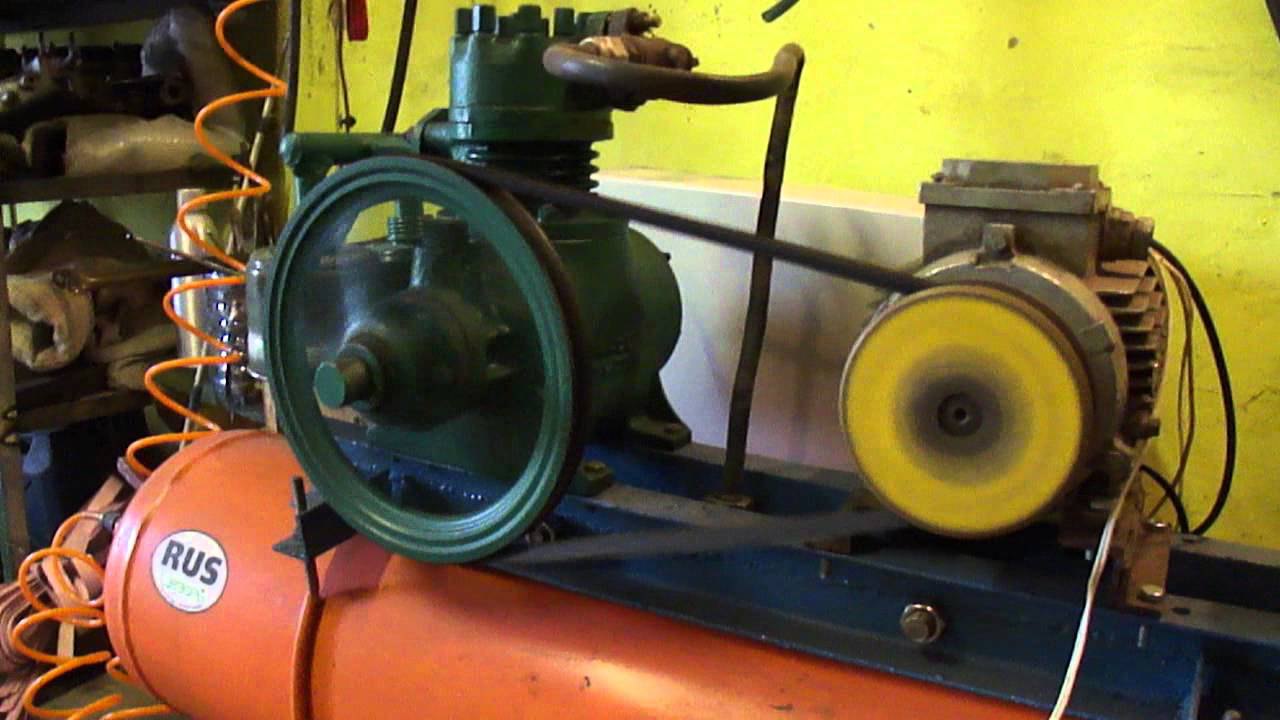

Homemade Car Air Compressor

If you want to make more serious equipment for painting a car based on an automated supercharger, read on. It should be noted that this home-made semi-professional compressor will cost more in terms of materials, so first figure out what you will use it for, and whether you need it at all.

What to make an automated supercharger?

To do this, you need the following set of materials:

Preparatory work

Any electric motor can act as a power unit, but such that the pressure switch produces the necessary results. Before operation, it is best to thoroughly clean the blower with an anti-corrosion agent. If any filter clogs, replace it. It is also useful to change the oil.

The supercharger should have three exits to the tubes:

- for air inlet;

- to change the oil;

- for air outlet.

You can determine where the outlet is and where the air supply is, by briefly turning on the engine. One tube must be sealed - to change the oil. When opening it, make sure that no sawdust gets inside. We will need an oil separator, as part of the oil can get into the air flows emitted by the supercharger. The filter should be screwed onto the air supply pipe, and clamps are better for fastening.

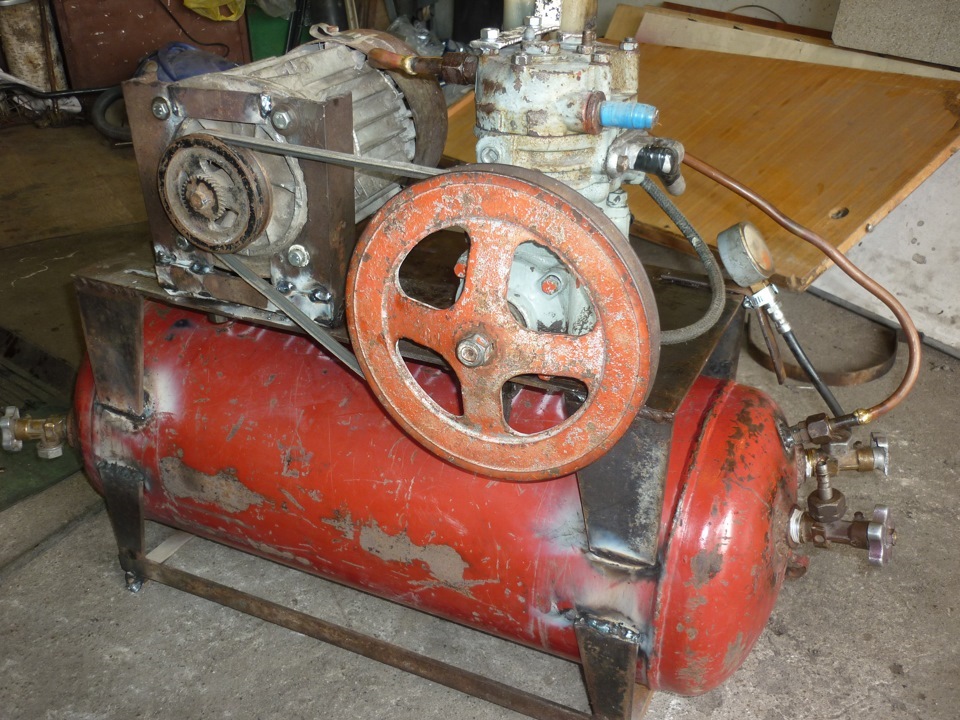

As for the receiver, a cylinder can play its role - from a fire extinguisher or gas. The main thing is that it withstand high pressure.

Getting started assembly

The receiver must be securely fixed to the shield. The main plane of the shield or stand may have mini rollers from old furniture. Check that a filter is installed on all necessary elements of the autocompressor. In addition to the fact that the autocompressor must have a coarse filter and an oil separator, it is important to take care of the presence of an air intake. You can do it yourself.

How to make an air intake

You need to take a tube through which the paint compressor will take water, and install a coarse filter in its place. After that, the filter should be connected to the gearbox. Without it, the pressure will not normalize. The outputs should also be connected to the receiver crosspiece. There will be two more crosses that can be used under a manometer or for connecting to a spray gun. In words, this all seems too complicated, but if you know the principle of operation, you can assemble the compressor for painting in the presence of a supercharger engine and a receiver.

For safety, in order to avoid connection breakdowns, it is necessary to turn on the compressor periodically. This is done using a relay. The best types of pressure switches today are PM5 and RDM5. They are the simplest switches, adjustable by springs. The supercharger is connected to the zero phase. Install a toggle switch on the main phase wire, as it may be necessary to turn off the device.

If you like to service a car with your own hands, without contacting a car service specialist once again, you should get the appropriate equipment. Among other useful things, you will need a system for painting a car - a compressor-spray gun.

If you look wider, you will need a compressor not only for painting the car. It is also used for other operations, such as sandblasting, inflating wheels and blowing different elements of the car. However, unlike other works, the specificity of painting is that it is necessary to ensure stable air pressure. Otherwise, streaks will appear on the treated surface, and the coating itself will be inhomogeneous and clogged.

Air compressor for car painting

Therefore, the compressor used for painting cars has special requirements for the stability of air pressure. In addition, the air flow when painting the car should not contain any foreign particles. This is necessary so that the surface of the car's painting is clean and even, without air bubbles and extraneous debris.

The simplest solution: in case of need, just purchase a suitable model in the store. , It will not be difficult, but this thing is quite expensive, and not everyone has the financial ability to buy it. In this case, there is another solution - you can do it yourself.

This process is quite time-consuming, requiring certain skills and patience. But if you want to make a homemade compressor for painting a car, any car enthusiast can. The main thing is that there is a desire and time.

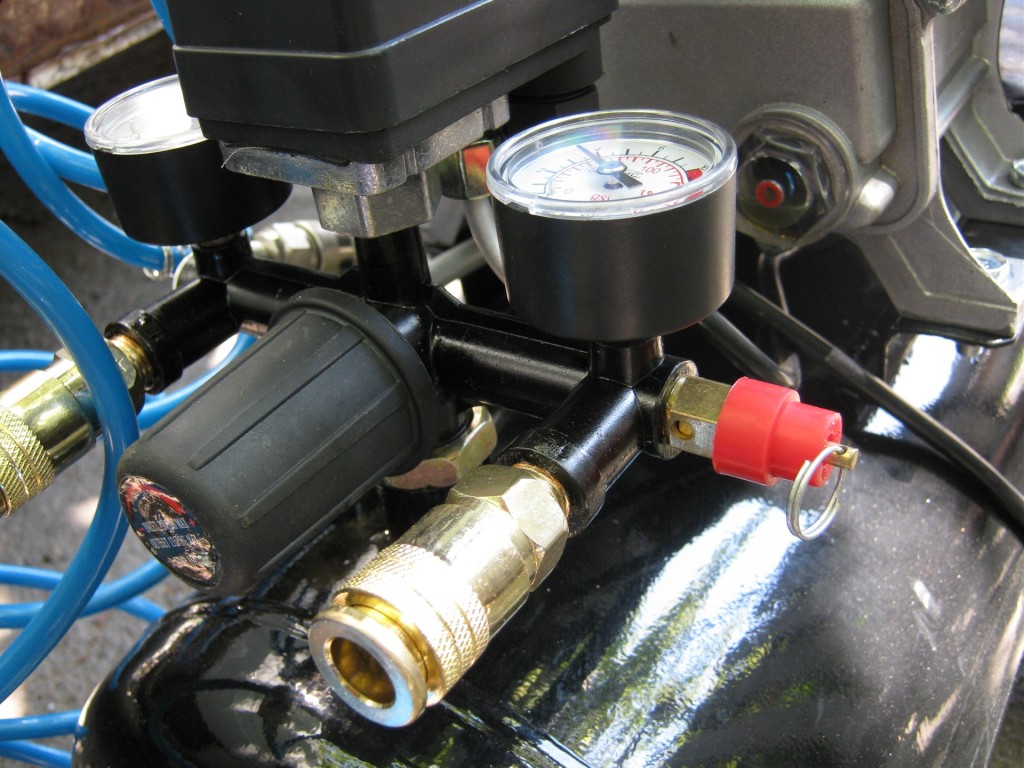

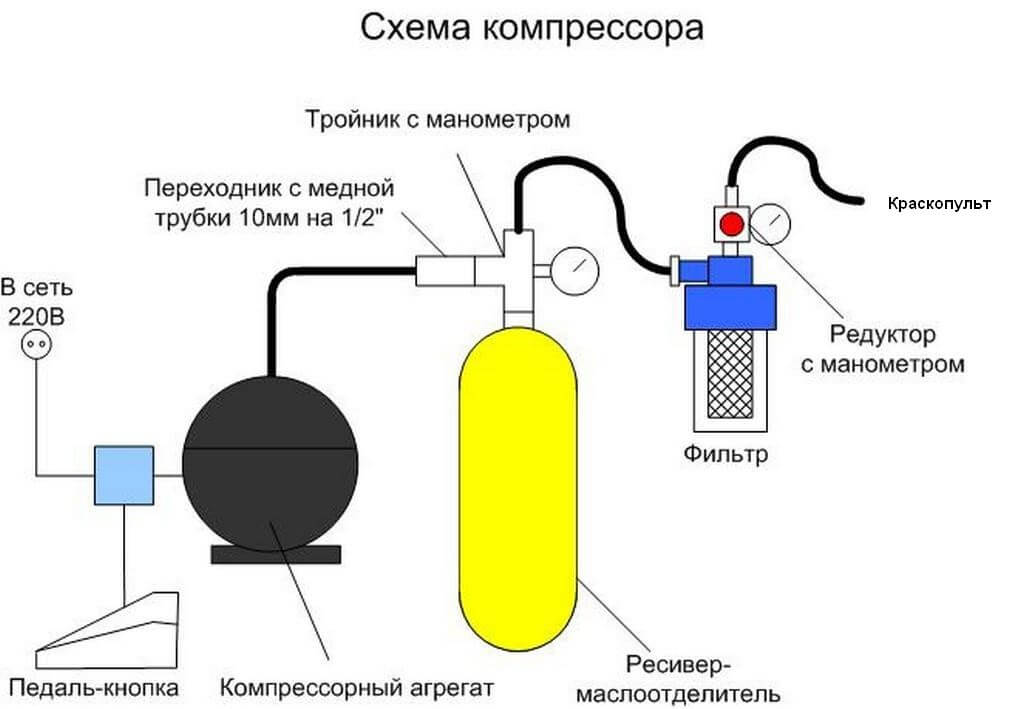

How is the compressor for painting cars

First you need to understand the principle of operation of such an apparatus. And serial factory products, and a home-made unit for a car, assembled with your own hands, will have the same principle of operation. By means of a pumping device, air is supplied to the receiver, where it is in compressed form and from where it enters with a given intensity to the spray gun from which the material is sprayed. Pressure control is carried out using a manometer. For the stepped operation of the whole mechanism, a start relay is used, which closes and opens the circuit at certain levels of air pressure in the receiver.

Compressor device

Compressor device We collect the necessary materials

The first stage of work is the accumulation of the necessary base of parts and materials. So, to make a do-it-yourself compressor for painting a car. You will need the following:

- motor from an old domestic refrigerator;

- cylinders from used ten-liter fire extinguishers;

- thick wooden board;

- motor oil (semi-synthetic);

- medical syringe;

- file for cutting metal;

- pressure gauge;

- electric toggle switch;

- filter for gasoline engines;

- filter for diesel engines;

- gearbox with oil and moisture purification filter;

- water crosspiece;

- brass tubes;

Materials required for compressor assembly

Materials required for compressor assembly - oil hoses;

- screw clamps;

- sealant tape;

- rust remover;

- 3 sheets of plywood;

- 220 volt toggle switch;

- enamel for painting metal;

- wheels from furniture.

After we have collected everything we need, we can get to work.

What to do with the motor

As a mechanism for pumping air into a makeshift device, it is best to put a compressor from an old Soviet refrigerator. You ask, why from the Soviet?

Because the motors in them are designed for heavy loads, they cope well with emergency situations and have a fairly large resource for durability. In addition, they have a start relay, which we will need for the stepped mode of operation of our unit.

After we remove the motor from the refrigerator, we must improve it with our own hands. Since oil tends to thicken over time, it is best for us to replace it. For this, we find 3 metal tubes in the compressor. 2 open are air inlet and outlet channels. The 3rd tube has a sealed end - this is a channel for replacing engine oil.

We use the motor from the refrigerator for our compressor

We use the motor from the refrigerator for our compressor First you need to decide on the air channels: which of them is the input and which is the output. We briefly apply voltage to the motor and observe where the air enters and where it exits. We make appropriate notes on the channels.

Now we can begin to change the oil - do it yourself is quite simple. Using a metal saw, we make an incision in a circle, and then carefully break off the sealed end, making sure that sawdust and debris do not enter the channel. We get rid of the old oil, and then fill the semisynthetics with an ordinary medical syringe. To seal the channel, we select a screw with a section of the appropriate size, wrap it with hermetic tape and screw it into the channel.

We change the oil in the refrigerator motor

We change the oil in the refrigerator motor How to make a do-it-yourself receiver

Now we need to make a container for compressed air. In the set of useful things that we stockpiled ahead of time, we find the cylinder of the used ten-liter fire extinguisher from the car. It is perfect for our purposes. We clean all dirt from it, grind the centers of corrosion. We remove the shut-off and start-up tap and pour in the rust control agent, shake it well, wait for the right time and drain. We screw a water cross in the neck - we can assume that the receiver on the compressor for painting the car is ready.

Old fire extinguisher instead of the receiver

Old fire extinguisher instead of the receiver Do-it-yourself assembly

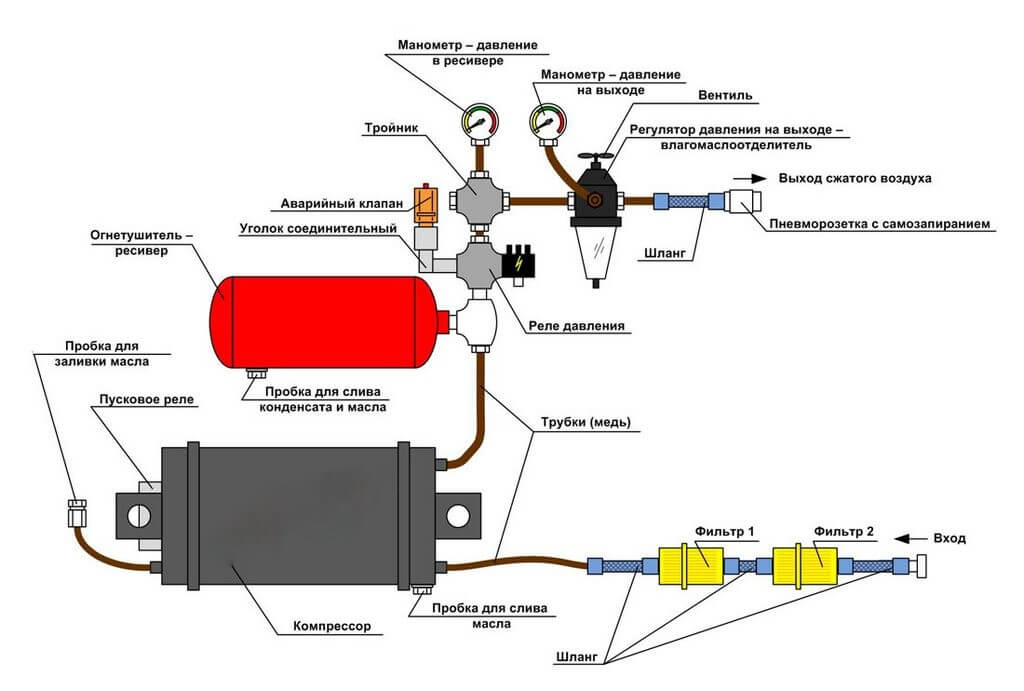

After the two main elements are ready, we can begin the installation. The above diagram shows the general structure of the unit for painting cars. To get started, you should study it well.

Compressor scheme for car painting

Compressor scheme for car painting We do all the work according to the algorithm below:

- As a basis we take a thick wooden board, we attach a motor to it. You should pay attention to how it will be located - it depends on how stable and correctly the starting relay will work. You must choose the same position in which the mechanism was in the refrigerator. Most likely, the relay will be marked accordingly.

- Vertically fasten the receiver. To do this, we make a hole of the corresponding diameter in one of the plywood sheets, put it on the container, and fix it on the sides with two other plywood sheets, fastening them with one edge to the base and the other to the worn plywood sheet. We carry out fastening with screws and glue.

- We put on a rubber hose with a filter for a gasoline engine on the air inlet channel of the supercharger. No great effort is foreseen here, therefore, additional fastenings are not necessary.

- We put a hose and an oil-moisture filter from a diesel engine on the exhaust air channel of the supercharger. As mentioned above, the air stream should not contain any impurities - otherwise it will adversely affect the quality of the car’s coloring. Since the airflow here will be quite strong, it is necessary to provide additional fastening with the help of special clamps on the screws.

Do-it-yourself compressor assembly

Do-it-yourself compressor assembly - We connect the filter to the gearbox and along the chain - to one of the side channels of the receiver crosspiece. The gearbox will provide stable pressure, which is very important in the process of painting the car.

- On the other hand, we include a pressure gauge in the chain to control the pressure.

- From top to top we wind with a fitting using a relay for adjustment. It will control the level of air pressure in the receiver and turn on and off the motor at the right moments.

- We solder all electrical contacts and carefully isolate them. We solder the on / off switch of the device into the electrical circuit so that there is no need to constantly use the power plug.

- Getting to the test. We put the regulator of the relay at minimum pressure and turn on the device. We look at its work, try different positions of the regulator, make sure that the relay turns the motor on and off at the corresponding air pressure values. Using a molar solution, we check the tightness of all air ducts. If we are satisfied with the inspection and tests, we carry out a control staining of some prototype.

We conduct a compressor test

We conduct a compressor test Conclusion

A compressor is a necessary part of the set of equipment in your garage. With it, you can perform the application of a paint coat on the car body, as well as various types of varnishes and primers.

Since the serial product is quite expensive, many experts recommend manufacturing. This is a complex and time-consuming process. However, it saves a substantial amount. To successfully complete the job, you will need certain skills in tooling, as well as patience and accuracy. Follow the recommendations described, faithfully carry out each operation - and the result of your efforts will be no worse than factory products.

Any car, both the oldest and the brand new, needs valiant care and timely repair. And this applies both to technical nodes and its appearance, inextricably linked with the condition of the car body. If finances are very bad or there is a desire to build something, the motorist will be able to assemble the compressor design for painting the car from improvised tools and operate it on a par with the purchased unit.

Necessity

A device made by a car enthusiast, if performed correctly, will work not only well, but even better than expensive equipment. It is because of the high price that the compressor for painting a car is increasingly being decided by users to make their own. There are many descriptions on how to do this in a virtual network. If you follow them exactly, then everything will work out.

Of course, you can try and get a model of an inexpensive automotive paint compressor, but the quality of such devices leaves much to be desired, and they will serve several times at best. We offer you to delve into the process of creating an air receiver with your own hands and find out its technological parameters.

Work principles

It is important for the future designer, as well as the painter in one person, to know how a homemade compressor works for painting a car:

- the engine drives air into the tank;

- in the receiver, the incoming air is under high pressure;

- through the relief valve, excess contents of the tank are introduced outward;

- when you pull the trigger of the spray gun, air flows are thrown into the barrel with paint;

- when the pressure level inside the device drops below a certain value, the engine turns on again, and the pressure begins to rise.

The presence of constant pressure inside the sprayer allows you to achieve a high painting result: the layer is even, the consumption of materials is moderate. It is important to adjust the pressure correctly.

Nuances

More details:

- The performance level of a paint compressor for a car depends on the volume of the tank. Therefore, when searching for a suitable device, it is worth giving preference to those that have a larger capacity.

- You don’t have to worry about searching for the engine: the gearbox from the refrigerator, which has remained from the Soviet era in the country or in the garage, is suitable.

- Liquid or dust getting inside the receiver is unacceptable. If this happens, all the painter’s efforts will be lost in vain, and painting activities will have to start from scratch.

- Choosing an engine from a refrigeration compressor, the master will receive a relay as a bonus, which will interrupt the air supply and resume it.

Problem of choice

You can choose devices for auto painting endlessly. Anyone who has such an opportunity, or there is a need to purchase branded devices to maintain the authority of the workshop, will make the choice of a car compressor for painting in favor of a solid branded unit with excellent characteristics and excellent reputation.

IMPORTANT! To understand the painter will help specialists selling goods and reviews of already held customers. It is worth discussing this issue in the forums or chatting with the masters at the service station.

Who often uses these devices knows that monotonous air supply under pressure is not enough for operation. Indeed, for each type of paintwork materials (paints and varnishes) you need to set special parameters for the pressure of the paint. In addition, the models manufactured by the company are able to turn off when a certain level of pressure is reached and adapt to operating conditions.

However, these devices also have a lot in common: they adapt to the same parameters of the power supply network - 220 V, are mounted on wheels and connected to the sprayer. The most characteristic parameters of domestic-made receivers.

How to make a decision

To find a device that is suitable for its characteristics, you need to study the catalogs of online stores, bypass local outlets with similar products. If you want, you can completely inspect the device, test it to the smallest detail, and then order the same unit from the manufacturer via the Internet.

It is worth delving into the classification of painting equipment so that there is a complete set of data for personal use. The equipment produced by well-known brands has an extended warranty period, which is also important for the consumer. On the contrary, brands that few have heard of are not worthy of the attention of serious buyers. For their production, components of the worst quality are used. As a result, system nodes break down, and while warranty repairs are being carried out, the painter has to lose valuable time.

Do not rush to purchase an unexplored device. By carefully studying the characteristics, the device that is really needed will be found. Whoever could not find his mischief of thousands of items with a brand name and symbols in the lists of online portals or on forums, helps his own ingenuity and descriptions from craftsmen how to assemble a compressor unit with your own hands. Independent production may be more durable, although not as functional as with modern conveyor production.

The best material for car trim

Principles of hardening the body

Do-it-yourself compressor - with minimal scrap costs

Which is better: do-it-yourself or factory-made compressor for painting a car

Causes of fuel pump malfunctions