Today, breakdowns of a gasoline pump are not uncommon. The culprit is only the drivers themselves. Among the main causes of these failures are the following:

- dirty or clogged fuel filters,

- frequent driver ride with an empty tank.

Regardless of these two situations, the gasoline pump runs at full capacity, so it develops its resources much faster. Therefore, the driver must remember:

Engine performance and maximum torque relative to cylinder capacity are increased. Turbocharging is a prerequisite for resizing: the goal is to reduce displacement while maintaining the same performance on the engine.

A fixed high-voltage ignition distribution is not activated mechanically, but by a fully electronic system. Therefore, the distribution of the ignition voltage is not subject to wear. Ignition time can be adjusted using a wide range of settings.

- firstly, that should fill at least half of the fuel in the tank

- secondly, periodically change the fuel filters, as the fuel is not always of high quality

The gasoline pump is one of the main components of the propulsion system of each car. Using it, the transfer of the combustible mixture to the engine is carried out. So, it connects the gas tank and the engine, which are located on different sides from each other. It is known that old car brands were developed without a gas pump, since fuel was supplied to the engine through the fuel hose using gravity.

We develop components and modules for modern automatic transmissions. We offer optimum driver comfort with fast and flexible gear changes while reducing fuel consumption and emissions. We supply electronic and hydraulic components for the control of automatic transmissions, continuously variable transmissions, dual-clutch transmissions and automatic manual transmissions.

Exhaust gas treatment

To meet more stringent emission standards, it is not enough to make combustion as clean as possible. It is also necessary to install an exhaust gas purification system. Our emission reduction solutions are very effective: in some major cities, the processed exhaust is cleaner than the surrounding air.

Today, automakers are equipping cars with mechanical or electric gas pumps. The first type is designed for carburetor type machines. In this case, the fuel at low pressure gets into itself. The electric model, on the contrary, delivers fuel to the engine under high pressure.

The principle of operation of mechanical gasoline pumps is that the fuel is sucked in from the tank and enters the engine cylinder. The components can operate at low pressure due to the fact that they are located close to each other.

Innovative design for universal use

They are compatible with a wide range of vehicles with gasoline or diesel engines and manual or automatic transmissions. Due to their compact size, they are as easy to install as conventional starters. Reliable technology for the entire service life, equal to the power of the vehicle.

The number of starting operations performed by the starter, in other words, its service life, has increased significantly for this special application. Thanks to its even more robust design, the starter can survive more frequent starts throughout the life of the car without damage.

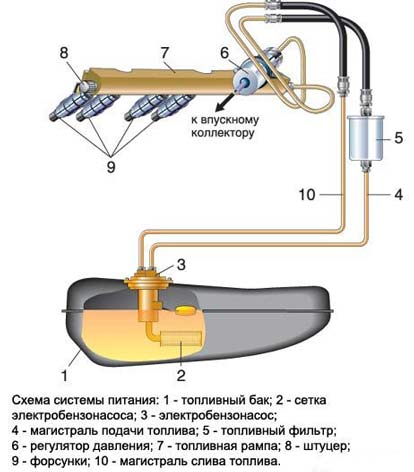

The scheme of the car's power system and the operation of the electric gas pump

Electric gas pumps operate at high pressure compared to the mechanical type. Thus, due to strong pressure, fuel is pushed into the engine itself. In older models of cars, the gas pump worked constantly unlike modern ones, in which its speed depends only on the requirements of the unit. The electronic system of the car is responsible for the operation of this type of gasoline pump. This system automatically calculates the position, the content of exhaust gases, as well as the ratio of air to fuel mixture.

The following measures have been taken.

- Reinforcement of bearings subjected to heavy loads.

- Improved planetary gear.

- Use of reinforced mechanical components to engage the gear.

- Optimize switches for longer life.

For a restart, it is enough for the driver to activate the clutch or, for vehicles with an automatic transmission, to remove the foot of the brake pedal to restart the engine. An attachment that extinguishes instantly. This cycle consists of a 7-kilometer trip with 12 stops of 15 seconds each.

It is worth noting that the electric type of gasoline pump is noisy and quickly heats up, as fuel is supplied to the engine under pressure. Because of this, such pumps are placed in the fuel tank, which allows the fuel pump to cool with fuel. In addition, due to this placement of the pump, its operation becomes almost silent.

Leaders of power and efficiency. Knowledge that pays off not only for motorists, but also for automakers. The latest examples of our competence and innovative ability are new generators for baseline and efficiency. Efficiency for various power requirements.

What problems can we face today? This phenomenon is accelerated by the use of unleaded gasoline, whose additives have a detrimental effect on old elastomers. Result: Membrane movements lose amplitude, and gasoline flow becomes insufficient.

This type of pump operates on a motor signal. After the ignition is turned on, the on-board computer signals the start of the gas pump, which is then supplied with an electric charge. The motor installed inside the pump starts to rotate for several seconds, after which pressure rises in the fuel system. If the computer does not receive a signal to start the engine within 2 seconds, the gas pump immediately turns off for safety reasons.

Symptoms: Difficulty starting after a long period of stop. Another effect, much more vile, is overheating of the pistons due to too low speed at high speed, for example, on a highway. The symptom is not easy to detect because the power does not drop significantly, but the effects are sharp in terms of engine breakdown, of which two are examples.

In the upper image, the piston aluminum “softened” under the influence of excessive temperature, and a section of fire used it to calm down a little. If the process takes too long, the image below, we observe an alloy of aluminum and a section of fire, which this time was the trunk! Imagine the condition of a cylinder liner.

Just the first two seconds after turning on the engine, the driver can hear the pump. After this, fuel enters through a special tube into the gas pump, after which it exits and enters the fuel filter, which cleans the fuel mixture from contaminants and debris. Therefore, in this sense, it is better to periodically change the filter so that it effectively cleans the fuel. Then the pre-cleaned fuel enters the engine itself. The gas pump continues to operate until the engine shuts off.

Now consider the various models of the original membranes that can be found on the pumps used. The test, which must be carried out imperatively to disassemble the pump, is the elasticity of the membrane. This is enough to pinch the latter between two fingers, not necessarily synthetic, and to observe the bending of the membrane under its own weight.

For comparison, let's now look at the specifications. of currently offered membranes. Let's go back to the other points that need to be controlled. In extreme cases, the spring may break and break through the membrane! Result: The 3rd cylinder receives too much gasoline through the perforated membrane. In the end, the crankshaft bearings will be damaged by this excess fuel.

An electric fuel pump is used on engines with fuel injection to supply fuel from the tank to the nozzles. The pump must supply fuel under high pressure (2 to 6 atmospheres) so that the nozzles can spray fuel into the engine. The fuel pressure must be within the limits set by the engine manufacturer. If the pressure is too low, the engine may starve, there will be acceleration with dips, poor traction, the speed limit is lower than usual. Too much pressure in the fuel system can lead to intermittent engine operation, increased emissions.

The front cylinder spark plug is heated repeatedly. Sometimes, due to the excessive tightening of various pump screws, the weld planes are deformed. Result: Even with new connections, fuel flows out of the pump. In addition, the lack of compaction will affect pump performance in terms of flow rate, outlet pressure and primer behavior. After a long shutdown, one of the valves does not stick to its seat, it also depends on the oil used for the mixture.

This is a pumping tool that works without continuous human intervention and includes the following three main parts: - An engine that provides the power needed to pump out. - A transmission shaft that transfers this power to the pump itself. - A pump, a hydraulic part that uses this power to transmit it to water and draw. Energy supply most often has a thermal or electrical origin. This sheet mainly refers to pumps used for drinking water, but the same types of pumps are also used for irrigation.

Electric fuel pumps are typically installed inside the fuel tank, although some are installed externally. Some vehicles have two fuel pumps (transfer pump inside the tank and the main fuel pump outside). The location of the pump in the fuel tank helps drown out the noise made by the pump motor, and dipping the pump in the fuel lubricates and cools the pump motor. Driving with a fuel tank less than 1/4 full, can shorten the life of the pump, as the pump will run hot. Also increases the risk of pump starvation during cornering, braking or accelerating.

Motorized pumps have been used regularly for several decades, mainly in urban areas where the water flows to be pumped cannot be obtained using hand pumps, but also in rural areas, especially for irrigation, and an emergency response.

The use of motorized pumps represents a significant advance over manual pumps since. There are no more flows and discharge heads: there is always a pump adapted to the needs in terms of flow and pressure. “They can work continuously for several hours without human presence, and even 24 hours a day for large pumping stations, which allows you to get much more water daily if there is a tank of sufficient capacity. Do not require any physical effort and allow you to quickly pump out large volumes of water at the moment when they are needed, unlike most hand pumps or solar or wind pumps.

Electric fuel pumps come in a variety of designs. Some older designs use volumetric “cell rollers” of construction. This type uses rollers mounted on an offset disk that rotates inside a steel ring. Fuel is sucked into the cells between the rollers and pushed to the exit. This type of pump can generate very high pressure and the flow rate is usually constant. At the exit, the fuel pulsates, therefore, in the fuel line, after the pump, a valve is often installed to weaken the pulse pressure. Pumps such as cell rollers can also be installed outside the fuel tank, and used with a second low-pressure pump installed inside the fuel tank.

The places or contexts in which this means seem most appropriate

Motorized pumps allow you to pump water with a selected, more or less high flow rate, continuously or not. These pumps are powered by gasoline, diesel fuel or electricity and should be easily accessible at an affordable price to the public so that they do not have problems with stopping due to lack of fuel, a power source.

They are suitable for water supply in large villages and in urban or suburban areas. Motorized pumps for drinking water can be divided into two main categories depending on the type of intake. Surface pumps, suction pumps, which can be motor pumps if they are equipped with gasoline or diesel engines or electric pumps, if they are equipped with an electric motor.

Another type of volumetric pumps, "gerotor" pumps. This design is similar to an oil pump, and uses the displacement of the rotor to push fuel through the pump.

Another option is the pump roller wing. Here, blades are used instead of rollers.

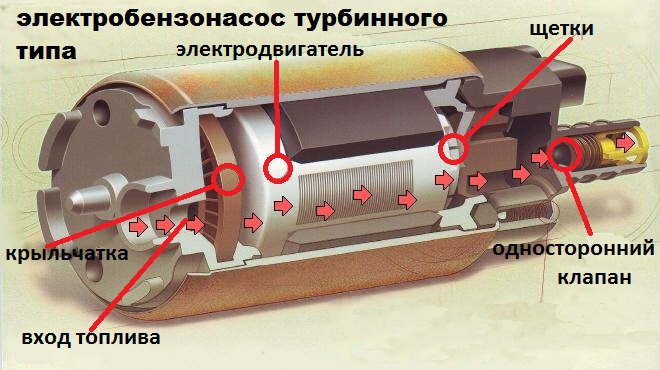

Most new cars use a “turbine” type of fuel pump. In a turbine pump, the impeller is attached to an electric motor. Impeller blades push fuel through the pump. This type of pump is not volumetric, therefore it does not produce ripples, it works smoothly and quietly. It is also less difficult to manufacture and very durable.

Shallow well pump - Capture a source or stream - Discharge into the network from the reservoir. Submersible pumps used for deep injection. They are most often equipped with an electric motor. In the absence of power supply through the grid, you can find pumps with a raw diesel engine and gearbox, but these rods are quite fragile and cannot be used at great depths. Alternatively, an autonomous power supply may be provided.

There are many patterns in each of these categories. For example, in Burkina Faso, this was already ten years ago. Motorized pumps are centrifugal pumps from the turbopump family. The fluid is aspirated in the axial direction under the action of the rotation of the wheel, equipped with ribs or blades in the pump casing, where it is accelerated radially in the blade before displacement. The shaft is driven by an electric or heat engine.

NOTE: When replacing the fuel pump, it is not necessary to set the same type as the original. But they must be able to generate the same working pressure and provide the same amount of fuel as the original.

How does an electric fuel pump work?

When you turn on the ignition, voltage is supplied through the relay to the fuel pump. The engine inside the pump starts to rotate and runs for several seconds to increase the pressure in the fuel system. A timer within the PCM counts down how long the pump will run until the engine starts.

Accuracy of power calculation: the power consumed on the pump shaft is determined by the following formula. Power consumption is equal to the division of power absorbed on the shaft by engine efficiency. It usually ranges between 0, 8 and 0. The pump should be selected so that the operating point is as close as possible to the maximum efficiency point specified by the manufacturer.

Therefore, before choosing a pump, it is necessary to consider all the characteristics specified by the manufacturer. It might be more profitable to buy a pump a little more expensive if it offers a better solution. Practice. "Small-scale irrigation." When you have a gun in your hand, you refuel your expensive car, have you ever wondered how it went from the tank to your tank? Of course, knowing the answer, he does not change the price paid, but he can entertain the mind with a time full! From the gun to the calculator through the volumetric pump, let's lift the curtain to the mechanism that pumps fuel and your money so fast!

Fuel is sucked into the pump through an inlet pipe and a strainer that protects the pump from rust and dirt. Fuel leaves the pump through a one-way valve (which maintains the residual pressure in the system when the pump is not running) and pushes toward the engine through the fuel line and filter.

The fuel filter traps rust, dirt, or other solid impurities that may have passed through the pump to prevent clogging of the fuel injectors.

Mechanical operation of the fuel pump

Let's see what makes up the main part of a gas pump or, in other words, its mechanical part. The first device, of course, is the engine. It controls the hydraulic unit, which is the heart of the volumemeter and consists of. Volumetric pump: this important part is the one that draws fuel into the tank to return it to your tank. It works continuously, but sucks in fuel only at the request of the user. - Bypass or non-return valve: it stops the suction of fuel in the tank.

Then the fuel enters the fuel rail and is directed to individual nozzles. The fuel pressure regulator in the fuel rail maintains the fuel pressure, and sends excess fuel back to the tank.

The fuel pump runs continuously as soon as the engine starts, and continues to work as long as the engine is running and the ignition is turned on.

Many cars have an “inertial emergency switch” that turns off the fuel pump in the event of an accident. This is to reduce the risk of fire in an accident. A sharp push opens the fuel pump circuit. After that, it is necessary to manually reset the emergency switch after tripping by pressing the reset button.

On most older cars, the fuel pump runs at a constant speed. But on many new ones, pump speed varies to more closely match fuel consumption.

Fuel pump failure.

The fuel pump should work for the entire life of the car, but it may fail due to contamination inside the fuel tank (dirt or rust), fuel starvation (running out of fuel), overheating (constant driving with low fuel level), low voltage (wiring problems) , or load (overcoming filter resistance).

Often the fuel pump fails suddenly. How can you identify problems with a gas pump. One way is to listen to the noise of the pump after turning the ignition key. The silence from the tank will tell you that the pump is not working. In this case, the pump may be defective, or the fuel pump relay, fuse or wiring may be defective.

On most vehicles, if the fuel pump fails, the Check (fault indication) will not turn on. The engine will spin up, there will be a spark, but it will not start because it does not receive fuel.

On most new engines, there is a fuel pressure sensor that quickly determines if the pump is giving any pressure. On engines that do not have sensors, there is a conclusion, for measuring pressure, in the fuel rail. If the fuel pressure is zero, the pump does not work. If the fuel pressure is less than specified by the specification, it is necessary to diagnose the system to determine the cause of the low pressure.

The best material for car trim

Principles of hardening the body

Do-it-yourself compressor - with minimal scrap costs

Which is better: do-it-yourself or factory-made compressor for painting a car

Causes of fuel pump malfunctions