It is noteworthy that the fuel pressure regulator on a VAZ 2110 car has a very low weight, it is very cheap compared to many auto parts. But at the same time, this device plays an indispensable, extremely important role in the functioning of the entire fuel system.

What can I say, fuel consumption, as well as engine power, largely depends on this sensor. Therefore, the owners of the VAZ 2110 should definitely know how this unit works, what are its main signs of failure, and how the sensor is replaced.

Device

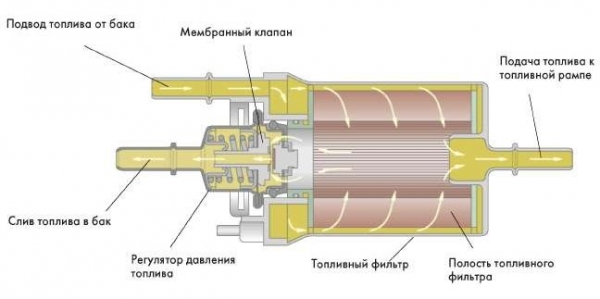

The regulator includes two cavities - fuel and vacuum. Inside the vacuum is a membrane that responds to air pressure that comes from the power unit. Inside the fuel cavity is high pressure fuel.

The fuel pressure is opposed by a valve device. If the pressure is excessively high, its excess amount is returned back by means of relief.

How the regulator works

The fuel regulator monitors the difference in the impact on the membrane from two sides, that is, both cavities. Only under such conditions will the engine be able to function normally.

The sensor serves to maintain pressure drops, regardless of the current engine speed. Fuel injection will not be possible if the pressure in the manifold is equal to or greater than in the nozzles. Nozzles must have higher pressures.

If everything works well, the following processes are observed:

- The vacuum in the cavity of the intake manifold is reduced with the quiet operation of revolutions;

- In response to this pressure, the fuel in the ramp and its supply to the nozzles increases.

Malfunctions

If the sensor starts to malfunction, this can be determined by the characteristic signs indicating the presence of a breakdown:

- The engine starts to run erratically;

- The motor cannot idle;

- Power disappears, its lack is felt;

- During movement, the momentum disappears for a while;

- Fuel consumption increases significantly;

- Emissions from the exhaust system increase;

- The car, which stood for a while, starts up hard, a prolonged rotation of the starter is observed.

All this tells the car owner that trouble happened with the fuel pressure regulator, it is urgent to intervene in the situation, to solve the problem as quickly as possible.

Check

If you find characteristic symptoms, we recommend that you first make sure that the problem with the car is related specifically to this sensor.

The inspection is carried out as follows:

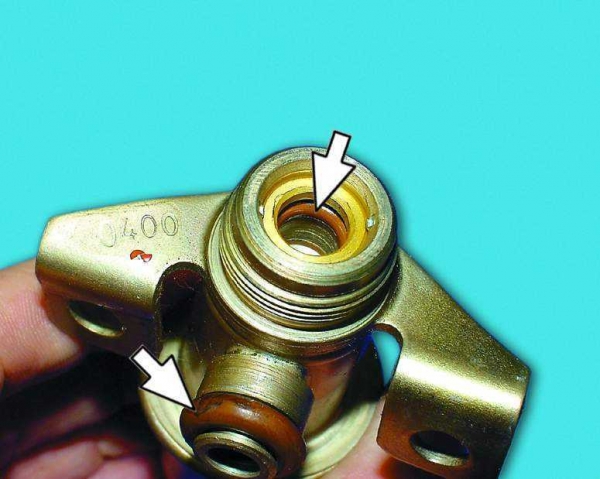

- On the end of the ramp block there is a fitting designed to check the pressure indicator;

- It is covered with a stopper, which you need to unscrew;

- On the bottom of this cork there is a ring that compensates for the distance;

- If there are traces of damage or defects on the ring, be sure to replace it with a new one;

- Now take the cap from the tire, and unscrew the spool with its back. It is in the middle of the fitting;

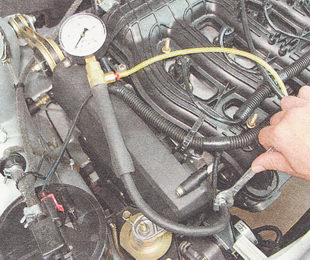

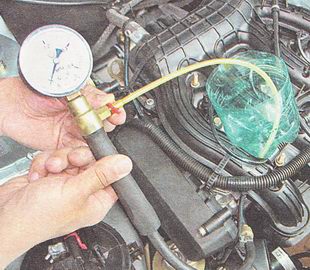

- Now the flexible hose from the measuring device is connected to the fitting. You can use the usual pressure gauge that you use when pumping wheels;

- Clamp the hose with a hose clamp and begin testing;

- Turn on the idle speed, because with it the vacuum is the lowest and the fuel pressure is the highest;

- Start the engine. The device should show 2.9-3.3 units;

- Now check the readings, only without a vacuum hose;

- Having removed it, the pressure gauge should give out about 0.2-0.8 units. If no changes have occurred, then the regulator is definitely out of order and needs to be replaced.

Replacement

The procedure for replacing the fuel pressure regulator on such a car as the VAZ 2110 can hardly be called complicated. Therefore do not rush to go to the station maintenanceto give a decent amount of money. And if this is a dubious car service, it is far from the fact that they will repair better than you do it yourself.

One way or another, every VAZ 2110 car owner should know about the sequence of replacing the fuel sensor.

For this:

- Relieve the load in the fuel system;

- Dismantle the return mounting from the fuel pressure regulator, remove the tube;

- Unscrew the two bolts responsible for fixing the unit;

- Remove the fitting;

- Remove the gas hose from the fuel pressure regulator;

- Get the failed fuel sensor;

- Put in its place a new device;

- During the reassembly process, it is recommended that you replace the old cuffs. After dismantling, as a rule, they lose their original working condition. Therefore, their repeated use will not allow them to function as before.

It is obvious that the fuel pressure sensor plays a crucial role in the functioning of the VAZ 2110, like any other car. Its condition should be treated with increased attention, timely response to ongoing changes, take appropriate measures if the regulator fails.

It is not difficult to do this yourself, and you will have to spend quite a bit of money. But if you are not confident in your abilities, you do not have the desire or trite time to engage in your own car, go to a proven, reliable car service, the quality of services of which you can be sure of. We do not recommend contacting any dubious workshops.

5. With a 14 mm open-end wrench, wrap the hose end.

RECOMMENDATION

If necessary, the pressure in the fuel rail can be measured with a homemade device, having made it from a manometer from the foot pump. Before connecting such a pressure gauge, it is necessary to relieve the fuel pressure (see. Fuel line - pressure relief). After that, turn the spool out of the fuel rail fitting. This can be done with the metal cap of the wheel valve. To connect the manometer to the fuel rail fitting, use a piece of a gas-resistant hose of suitable diameter. The ends of the hoses must be securely fixed with clamps.

6. Turn on the ignition on the car. In this case, the fuel pump will work for several seconds. After waiting for the pump to stop working, turn off the ignition.

7. To remove air from the pressure gauge, lowering the end of the drain pipe into a small container, we turn off the bleed fitting of the pressure gauge by 1 / 3-1 / 2 turns, and relieve the excess pressure of gasoline from the fuel rail. This will remove air from the pressure gauge hose.

On the VAZ 2110, the fuel pressure regulator is designed to maintain a constant pressure in the fuel system in any operating mode.

The RDT is a diaphragm valve that is installed in the fuel rail. On the one hand, gas pressure is applied to it, on the other hand, springs and air from the intake manifold.

Signs of breakage

If for some reason the fuel pressure regulator does not perform its functions, then this can be understood by the following signs:

- The engine has become unstable, it may start to stall when idling, although it would seem that the fuel level is enough, all systems are in good working order;

- The crankshaft idling has increased or, conversely, reduced speed;

- The engine, as they say, "loses throttle response";

- During movement, dips and jerks occur in a running engine;

- Gasoline consumption increases compared to what it was before;

- The content of CO and CH in the exhaust increases;

- The engine starts with difficulty. Although this property is not always manifested.

If the regulator has become completely unusable, then an increase in fuel pressure is observed. Instead of the norm for VAZ 2110, a component ranging from 2.5 to 3.3 kg / cm2, it reaches 4-5 and even more.

Consequently, the fuel pump delivers more gas in volume, which does not completely burn out, and cost overruns are guaranteed. Of course, such a regulator needs a replacement, and the sooner the better.

If the fuel pressure regulator does not provide the desired pressure, or simply does not hold, then the lack of fuel pressure level leads to the fact that normal flow does not occur, and the VAZ 2110 “suffocates” when it is necessary to increase the speed.

In addition, the starter can not quickly spin up the engine, you have to turn it on repeatedly.

FLS

It is quite understandable that we will first of all learn about gas overspending by the readings of its level sensor. However, sometimes the FLS also begins to lie, and then the true expense cannot be found.

There may be a situation when you still have half a tank of gasoline, and the FLS says that the fuel is almost at zero. That is, the flow sensor itself can confuse you, and before rushing to replace the regulator, make sure that the FLS is working, remember that the VAZ 2110 has very frequent problems with it.

If you notice that he is cheating, it may be necessary to adjust, or even replace the fuel sensor.

RTT verification

So, the sensor is already in order, but there is a fuel overrun, other malfunctions indicating that the regulator jams. First of all, check it out.

It is done like this:

- It is necessary to unscrew the plug of the fitting responsible for monitoring the fuel pressure. Look, if the seal ring is torn or just has ceased to be elastic, it (and even the entire plug) needs a replacement;

- Unscrew the spool from the fitting, this is done exactly the same as in any tire;

- Using a tire pressure gauge secured with a clamp on the fitting, measure the pressure with the engine running. It should be within the normal range;

- When disconnecting the regulator's vacuum hose, the pressure should increase slightly (by 0.2 - 0.5 kgf / cm2). If this does not happen, it means that there is only one way out for your VAZ 2110 - you need to replace the solid propellant. On average, the price of a standard RDT fluctuates around 300 rubles, an analogue of a solid propellant fuel exchange engine costs about 600 rubles.

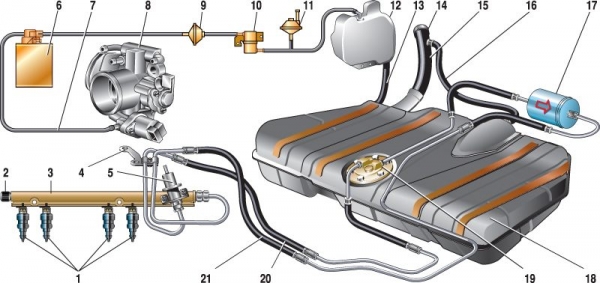

If the electric circuit in the VAZ 2110-2112-2170 car is known to be working, and the pump is buzzing as usual, this does not mean that gasoline is supplied to the injectors in the normal mode. Not! There may be some malfunctions. Let's start with the most basic.

To begin with, remove the protective cap of the nozzle (as shown in photo 1), be sure to put a cloth on the bottom so as not to splatter the engine compartment with fuel, and with the tip of a thin slotted screwdriver, press the nozzle spool. If the trickle of fuel is thin, weak, this means a low pressure in the fuel rail needs to be found. If gasoline sprays with a high pressure, then there is hope that the pressure is within the normal range (2.8-3.2 bar), but for certainty it is necessary to measure it with a manometer. At the service, this is done with fuel gauges with adapters.

We will use simple from the tire pump. The main thing is that the measurement limit is at least 4 bar. It will take another part of a gas-resistant hose, the length of which should be 150 millimeters, the inner diameter of which should be 10-12 mm. , as well as 2 more clamps. Use the wheel valve cap to unscrew the spool from the fuel rail fitting. We put the pressure gauge hose on the fitting and tighten it with a clamp.

We turn on the ignition, without starting the engine: after 2 seconds, the gas pressure in the ramp should increase to 2.8-3.2 bar and be held at this level (photo 3). If it is significantly lower (about 1 bar) and keeps at this level for a long time, it is necessary to check the supply line 4, apparently, it is clogged. There are 2 problem areas: the fuel pump grid 2 and the fuel filter 5. First, check the filter. It is located under the underbody next to the gas tank (photo 4). If it is in order, you need to look at the pump grid.

We take out the gasoline pump from the tank, remove the grid and rinse. Before installing the gas pump, it would be nice to check it for leaks and the reliability of the connection of its pipe (arrow in photograph 5) to the fuel line. You will certainly ask what to do if the supply line is clean, the pump is buzzing, and the pressure is still below normal. In this case, you need to change the pump itself, it has developed its resource! P And it can happen, so that the pump seems to function normally, but there is no pressure in the ramp! This can happen in winter if there is a lot of water at the bottom of the fuel tank.

P When freezing on the grid, it interrupts the flow of fuel to it. How to be To make a fire under a gas tank, to warm it with a blowtorch or some other source of fire, this should not be done under any circumstances. It is preferable to remove the petrol pump and clear it of ice. The second option for leisurely: to roll a car in a warm room and wait. Then it would be nice to pour water from the fuel tank. The case is troublesome, however, grateful.

So we made sure that the pressure in the ramp is within normal limits. Does fuel enter the engine cylinders? This is not a fact! Nozzles can become clogged, gasoline supply decreases, and maybe completely stops. However, sometimes a control signal is not supplied to the nozzles, although they themselves are in good condition. Control must begin with an inspection of the spark plugs.

If the candles are wet, then, therefore, gasoline arrives. Dry? In this case, you need to check the signal on the connector of the bundle of a mechanical liquid or gas atomizer (nozzle) with a probe (as shown in photo 6). Done, but are the candles still dry? Then you have to unscrew the screws securing the ramp and raise it under the intake manifold so that nozzle nozzles are visible. We turn on the ignition and crank the engine crankshaft. In the absence of streams of fuel, it is necessary to remove nozzles and most likely to replace with new ones.

True, in almost every serious service you will be advised to rinse them. Ask about the prices: if the price of a new set of nozzles is slightly higher than the flushing, then you should prefer a replacement. After all, old nozzles also have age-related problems. Taken from: http://autoshas.ru.

The best material for car trim

Principles of hardening the body

Do-it-yourself compressor - with minimal scrap costs

Which is better: do-it-yourself or factory-made compressor for painting a car

Causes of fuel pump malfunctions