M installation of the heating system is a responsible occupation that requires not only certain skills, but also an understanding of all its components. Expansion tank for heating closed type - This is a component that prevents the appearance of excessive pressure in the system. What it is, what kinds it is and how to embed it in the system, we will now tell.

Principle of operation

To understand how this device works, you need to return to school knowledge in the field of physics. This tank takes in the "excess" water that occurs when heated in the heating system. After the coolant cools down, it directs this reserve back into circulation. The term broad fully conveys its purpose. This can be explained as follows: when the fluid in the heating system heats up, it tends to expand and therefore the “excess” volume needs to go somewhere. And it is the expansion tank that readily accepts this surplus.

What are the types of this device

Since we are talking only about a closed-type system, it is about the expansion tanks that take away excess pressure that we will tell. First of all, I would like to note that on store shelves you can find a variety of sizes and types. Only red can be used for the heating system, as they are designed for high temperature. Expansion tanks are classified according to the type of membrane included in their composition. She may be:

- Fixed

- Removable

The first type is characterized by the presence of an integrated membrane, it divides the tank into 2 parts and presses it against the wall with the pressure of the injected air. When the water in the system is heated, its increased volumes, that is, its excess, goes into the tank, while the membrane moves away and compresses the air that is available in another part of the membrane. When the water in the tank cools, it is sent back to the system. This type is very reliable, but only on condition that the pressure in the expansion tank of the closed type heating is controlled, that is, the presence of air in it.

The second type is a rubber tank, which is located in the middle of the tank. When excess water gets into it, it accumulates in this rubber container and does not directly contact the tank. It is interchangeable, which means that if it is damaged, it can be easily replaced. Although experts have noticed that a fixed membrane is most often made from better materials, it is less likely to deteriorate, while the quality of a replaceable one raises serious doubts. Replaceable often deteriorate also because there is measured pressure on its lower part, thus uneven loading leads to breaks and leaks.

There are differences in the size and shape of the tanks, respectively, they have different volumes, which before you purchase, you need to calculate in accordance with the needs of your system.

Calculation of the expansion tank

Before you buy an expansion tank, you need to find out exactly what its volumes are needed. You can, of course, turn to numerous specialized firms, which, using special algorithms, will calculate the required amount. This is not just a calculator, but a whole miscalculation algorithm that allows you to take into account all the nuances. They can affect the stability of the system. This is of course very good. But also very expensive.

You can use special formulas. But here it is important to carefully calculate everything, because a very small error will make the final result incorrect. Here, many factors are taken into account, the volume of the heating system, the type of coolant used, expansion indicators, pressure.

Expansion tank for heating a closed type, its calculation looks like this:

V \u003d E * C / (1-Pmin / Pmax) / K app

FROM - This is the total volume of coolant.

E - coefficient that shows the expansion of the coolant. It is important to take into account the maximum permissible temperature at the time of operation of the boiler.

P min - primary pressure in the tank, it should not be less than the hydrostatic indicator of the system in general, exactly where the tank is located.

P max - This is the maximum pressure that can be reached in the tank. Here it is necessary to take into account the height difference, which can affect the pressure, as well as the location of the fuse valve.

To app - This is an indicator of filling the tank. It is expressed as a percentage, this is the ratio of the maximum volume of liquid to the full volume of the tank.

When the size of the heating system is taken into account, then all its components are included in it, that is, radiators, if any, a boiler and other elements. You can focus on the following data:

- Boiler room - 13 l / kW.

- Warm floor or other heating surface - 17 l / kW.

- Heating system, average value - 11 l / kW.

- The convector of the heating system is 8 l / kW.

- The convector of the ventilation system is 10.5 l / kW.

- Radiators - 15 l / kW.

It does not take into account data about the volume of accumulating liquids.Another option for calculating the expansion tank of a closed heating system is an online calculator, in which you need to specify all the same data as in the formula, and here you can have full confidence in the accuracy of the result, provided that all the data are correct.

Expansion tank calculation calculator for heating system

The heating system of a private house is a complex engineering structure, consisting of a large number of elements that perform different functions, and some at once. Such a device is an expansion tank for closed-type heating, which is an essential part of the heating system circuit. Expansion tanks regulate the volume of water and pressure in the system, and also perform other important functions.

An expansion tank for a closed heating system, as well as for open ones, is needed in order to compensate for temperature changes in the volume of liquid in closed heating systems. It is also known from physics lessons that when heated, water increases significantly in specific volume, and since the system is closed, the volume needs additional space in the heating elements. An expansion tank is required for this task.

This device can not only take in excess liquid that has arisen during heating of the coolant, but also when water is cooled, it will make up for its lack.

The use of an expansion tank is necessary due to the fact that when water is heated at 10 ° C, it increases in volume by 0.3%. Because of this, during heating in the system from 10-15 ° C to 80-95 ° C, its volume will increase by 2.4-2.8%. And if the system the amount of coolant is 100-300 liters, when heated, the difference in volume can reach from 2.5 to 8 liters. And this is already a sufficiently large amount of water that can lead to pipe rupture.

To avoid this, it is necessary to install an expansion tank of a suitable type and sufficient volume. When heated, it will have to receive excess water and vice versa, when cooled, the coolant will enter the system.

IMPORTANT!

Expansion tank need:

- so that it is possible to remove excess coolant from the system during its heating, as well as for the drain during exceeding the maximum tank level;

- to maintain the necessary hydrostatic pressure in the circuit by adjusting the volume of the coolant;

- for the accumulation and removal of vapors and air from the liquid coolant that appear during heating. As a rule, water contains up to 40 milligrams of air per 1 liter. When heated, almost 90% of this air takes the form of bubbles. An expansion tank helps to drain excess air into the atmosphere.

In the absence of an expansion device, during a temperature increase the hydraulic pressure in the system increases, and due to the fact that water does not have such a property as compressibility, this can lead to the destruction of the heating system. The compensated pressure in the expansion tank protects the system from ruptures in the pipeline.

Types of heating circuits and expansion devices

The expansion tank device is of the following types:

- open expansion tank for heating;

- closed expansion tank equipped with a replaceable or non-replaceable (diaphragm) membrane.

Each scheme has both pros and cons. But, nevertheless, the most popular today is a closed system with forced circulation. This scheme is compact, lightweight and faster installation. She also has a number of other operational advantages.

The main distinguishing feature is that in a closed system, the coolant is circulated by means of a circulation pump. It does not create excess pressure, but simply pushes water through the pipes at a certain speed. In this heating system, an expansion tank is installed for heating a closed type or, as it is also called a membrane expansion tank of the heating system.

It deserves its name because of its design, which is a sealed container divided into two parts using an elastic membrane. In one part there is air, the other serves to accommodate the excess coolant. Due to the presence of a membrane in the tank, it is also called membrane.

An open heating system does not provide for the installation of a circulation pump. In such a system, an expansion tank for heating can be any capacity, even a bucket, to which pipes from the heating system are connected. For such an open expansion tank, not even a lid is needed, although it can be equipped with it if desired.

The simplest option for heating an open type is a welded metal tank, which is mounted in the attic. This design has a rather serious drawback. Due to the fact that the tank is not sealed, the coolant evaporates over time and you need to constantly monitor its amount, topping it up from time to time. This is usually done manually using a bucket.

This is very inconvenient, since there is a chance to forget to replenish the coolant reserves and this can lead to airing and, as a result, a breakdown of the system.

It is more convenient to mount automated level control. But in this case, in addition to heating pipes, the water supply will also need to be drawn into the attic, and in addition, an overflow hose (pipe) must be removed somewhere in the event of a tank overflow. But there is no need to constantly monitor the amount of coolant.

Design and principle of operation of a closed tank

The design of a closed expansion tank for the heating system looks like a cylindrical tank with a rubber membrane installed inside, which separates the inside of the tank into air and liquid chambers.

The types of membranes are as follows:

- cylinder membrane tank for heating, the coolant in this design is inside the rubber tank, and outside the air or nitrogen under pressure;

- in the form of a diaphragm that separates the inside of the expansion tank closed system heating in two compartments - with water and injected air or gas.

The gas pressure is regulated individually for each system, this can be found in the instructions attached to such devices. Some tanks provide, if necessary, the possibility of replacing the membrane. This slightly increases the initial cost of the device, but subsequently, if the membrane is damaged or destroyed, it can simply be replaced, which will be much cheaper and more profitable than replacing the entire tank.

The shape of the membrane does not in any way affect the efficiency of the devices, it is only worth noting that much more coolant is contained in the closed balloon expansion tank for heating.

For expansion tanks of the heating system, the principle of operation is absolutely the same - with an increase in the pressure of the coolant in the network during heating due to expansion, the membrane stretches, thereby compressing the gas located on the other side and thereby allowing the excess coolant to enter the tank. As soon as the temperature of the coolant drops, the process occurs in the reverse order. Thanks to what there is an automatic regulation of pressure in a network.

It is worth emphasizing that if you buy an expansion tank for the heating system without the appropriate calculations, then it will be quite difficult to achieve the stability of the heating system. If you install a larger tank than necessary, then the pressure necessary for the system will not be created, and if you take a smaller one, then it will not be able to contain the excess volume of the coolant, which can lead to an accident.

Calculation of the volume of expansion tanks

In order to calculate the expansion tank for a closed heating system, for a start it will be necessary to calculate the total volume of the system, which consists of the volumes of the pipelines of the circuit, boiler and heating appliances.

The volumes of the boiler and radiators can be found in their passports, and the volume of pipelines is determined by multiplying the area of \u200b\u200bthe internal cross section of the pipes by their length. If the system has pipelines of different diameters, then it is necessary to calculate their volumes separately, and then add them.

Further calculation of the expansion tank for a closed heating system is carried out according to the formula:

V \u003d (Vс x k) / D,

where: Vс is the volume of the heat-carrying fluid in the heating system, k is the coefficient of volumetric thermal expansion adopted for water 4%, for 10% ethylene glycol - 4.4%, for 20% ethylene glycol - 4.8%; D is an indicator of the effectiveness of the membrane block.

Usually it is indicated by the manufacturer or it can be determined by the formula:

D \u003d (Pm - Pn) / (Pm +1),

where: Rm is the maximum possible pressure in the heating network, usually it is equal to the maximum working pressure of the safety valve, Rn is the initial pump pressure of the air chamber of the expansion tank, it is taken as 0.5 atm. for every 5 meters of the height of the heating system circuit.

The task of expansion tanks for heating is to provide an increase in the volume of coolant in the network up to 10%, which implies that if the volume of the coolant in the system is 500 liters, the volume together with the tank should be at least 550 liters.

According to this, the expansion tank must have a volume of at least 50 liters. This method of calculating the volume is quite approximate, which may entail additional financial costs for the purchase of a large volume unit.

Features of mounting the membrane type tank

After all the calculations are completed, you can begin the installation of the expansion tank. A rather important point is the choice of its location in the general scheme. This is influenced by the type of system - gravitational or forced circulation. Despite the fact that the essence of the task of the expansion tank in the heating system does not change - incorrect installation can cause malfunctions during operation.

Installation of the membrane expansion device in the heating system is done only on the return pipe in front of the circulation pump. One of the prerequisites is compliance with the premises. temperature condition. The level of air heating should not be less than + 5 ° С. Foreign objects must not interfere with the installation. This requirement also applies to the maintenance of the structure.

The correct installation of the expansion tank in the heating system is to comply with its level. The device should be placed strictly upright. Even a slight deviation can cause malfunctions of the entire system. In order to ensure safety during maintenance, it is necessary to install an air valve on the air chamber in order to be able to relieve pressure more quickly at the time of an emergency.

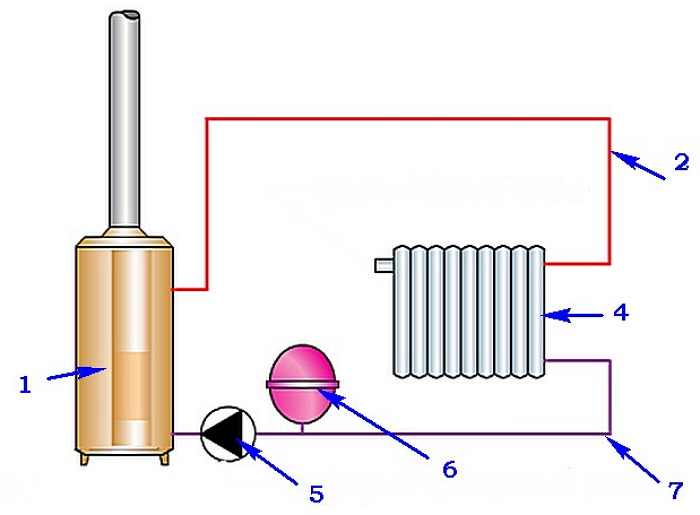

For someone who has special skills for plumbing operations, it does not take much effort to install an expansion tank. How it should crash can be seen in the diagram:

On the return pipe (position 1), as close as possible to the entrance to the boiler (position 2), but usually in front of the circulation pump (position 3), it is necessary to make a cut where the tee should be packed (position 4). Installation methods are different - it all depends on what type of pipes are used - polypropylene, metal-plastic or metal.

A ball valve (key 7) is packed onto the pipe (key 6) of the direct expansion tank (key 5). It is needed to provide the ability to disable the expansion tank if necessary, the implementation of prevention or repair. For such cases, it is also worthwhile to establish a connection with the union nut - “American” (position 8) between the tap and the tank. During operation, the crane must always be in the open position.

To the tee from the tap is the connecting section of the pipe (position 9). Its length and configuration (the number of turns and bends) do not matter much - but as a rule this is done along a more convenient and shorter path from the place of installation of the tank to the pipe with return.

The main difference between the operation of the expansion tank in a closed heating system is that it is possible to quickly dismantle it. To do this, it is necessary to install 2 shut-off valves at the time of installation - one on the inlet pipe to the heating system, and the second on the water chamber of the tank. Their cover will allow you to quickly dismantle the tank for repairs or replacement with a new one.

Installation of an expansion tank in a closed and open heating system

- Types of expansion tanks "\u003e Types of expansion tanks

- Installation of sealed tanks "\u003e

- Installation of leaky tanks "\u003e

- Tank tuning and repair "\u003e Tank tuning and repair

The first part of this article describes how to install an expansion tank in a closed heating system, in the second - everything about installation in open systems. You will also be able to find out where it is better to place the tank, how to check it, if necessary, repair and adjust. In addition, the text contains useful tips and describes common installation errors.

Types of expansion tanks

An expansion tank is needed to compensate for fluid expansion during heating. It can be leakproof with a membrane or leaky. In the latter case, it is an open container in which the liquid is in contact with air. Based on the structural differences of these two products, we can conclude that they are also used in different cases. There are two types of heating circuits:

- static - in them the circulation of the coolant is carried out by gravity under the action of gravity;

- dynamic - in them the coolant is pumped by the pump, without which circulation is impossible.

In the first, leaky tanks are installed, and in the second, a membrane expansion tank is installed. Both heating systems are never prevented by an additional supply of space where the expanded coolant will be forced out.

Installation of sealed tanks

Installation of an expansion tank in a dynamic (closed) heating system is carried out at any point in the circuit. This is so, but not quite. Still, there are important aspects to consider. Below are a few examples where you can not install an expansion tank in the heating system:

- do not mount the expansion tank after the pump. pumping pressure in the circuit.

How to install an expansion tank in the heating system? Directly behind the pump is definitely not possible, this will lead to constant jumps of the pressure gauge needle. The thing is that the sediment constantly builds up pressure, which is higher in the area behind it than in the return. Tank operation under such conditions will be incorrect. Technically competent and rational will be the installation of an expansion tank in the heating system in the return area of \u200b\u200bthe coolant. He, passing along the contour, experiences the force of friction and resistance. This reduces its speed. In addition, passing through the entire cycle, the coolant gives off its heat and, accordingly, decreases in volume. All these factors accompany a decrease in pressure in the heating system. And as a result, it turns out that the pressure on the return of the coolant is slightly less and it is more stable than immediately after the pump;

- do not install an expansion tank in the direction of the coolant immediately after the boiler.

Installation of the expansion tank in a closed heating system immediately after the boiler cannot be performed, because in this section the highest temperature of the coolant. The fluid at this point is in a state of maximum expansion for a given circuit. Therefore, the pressure there is higher than in the whole system. Do not forget that the tank is adjusted to a certain pressure in the system, and deviations can lead to drops. The instability of pressure in this area can also be caused by the presence of a built-in pump in the electric boiler;

- it is undesirable to position the sealed tank so that the liquid rises into it.

The expansion tank must be installed in the heating system so that the nipple of the air chamber faces down. It's all about the air, which may be in the circuit. The membrane tank is airtight. There is no connection between the cameras separated by a membrane. If you install the tank in such a way that the coolant will descend into the tank, then all the possible air will not be able to get there. Since, according to the laws of physics, he is pushed up and he can successfully reach the place of his exit outside. The system provides for installation at the highest point of the air vent. This is a valve that automatically bleeds air from the circuit. Also in the radiators of the modern sample, at the top at the end, there is a bleed valve for air, which operates in manual mode. Before installing an expansion tank in the heating system, it must be remembered that the membrane tank cannot remove air from the system. If the nipple looks up, then the passing air bubbles will certainly be in the tank. After that, it will no longer be expelled, which will gradually lead to a decrease in the useful volume of the tank.

Put the expansion tank in front of the boiler on the return line, there you need to put a pressure gauge. Since in this area stable pressure.

An expansion tank for heating a closed type is installed by means of special fittings, popularly referred to as "American". This is a type of connection that can be easily unscrewed, while it is reliable and tight. Its design consists of two parts that do not have a threaded connection. When wrapping it, you can not use tow or sealant, since there is a sealing gum inside. If American women were not used during the installation of the expansion tank, and it was planted tightly, then further maintenance becomes difficult.

Before installing an expansion tank for heating, it is necessary to put a tap. This will allow for routine maintenance and to check the operability of the tank. To determine the serviceability of the tank, before starting the boiler, it is necessary to block the access of the working fluid to the tank by shutting off the tap. Then turn on the system and do not open it until the needle on the gauge scale reaches one. After this, open the valve and observe the pressure gauge. If the tank is working properly, the pressure will reach 0.2 atmospheres, as excess liquid will squeeze into it. A common mistake made when installing an expansion heating tank of a closed type is the installation of a crane after an American, in front of the tank itself, and not before it.

For example, the membrane is torn and the problem must be fixed. There are collapsible models of tanks, but there are collapsible. In collapsible, only the membrane can be changed, but non-collapsible change entirely. In any case, it is necessary to remove the tank from the circuit. We turn off the faucet that stands after the American, and all the coolant will flow out of the system after the expansion tank for heating has been removed. If the installation scheme was correct, and the crane stood before the American, this would not have happened.

The expansion tank is attached to the wall. To do this, ears are welded to its body, with holes for fasteners. If such fasteners are not provided in the tank design, a universal fastener with a clamp can be used. First, it is mounted on the wall, and then a clamp is tightened around the tank.

Installation of leaking tanks

An expansion tank is installed in an open heating system at the highest point in the circuit. He often does not even have a lid. Its main purpose is to protect the coolant from debris entering it. It turns out that the water in the tank is in contact with air. This aspect is one of the disadvantages of this system. An increased level of oxygen in the water leads to the destruction of the pipe walls. Air reacts with the metal and the more it is, the more destructive the effect. A properly installed tank, in addition to compensating for changes in the volume of the coolant, it also removes air from it. Since it is the highest point in the system. Open heating systems operate without pumps. The fluid in them circulates by gravity. Such systems are made at an angle. The coolant moves slowly, more slowly than in closed systems.

There are several options where to install an expansion tank in the heating system:

The first and most classic option is to install an expansion tank in the heating system on a riser, directly above the boiler. In this case, the coolant heated in the boiler rises and not only moves along the circuit, but also enters the tank. As a result, there is always a high temperature, sometimes even boiling, if errors were made in the calculations. In this case, the tank will make sounds similar to those that appear when the kettle boils. Not a whistle, but audible well;

In an open type expansion tank for heating installed on the return, the coolant will be colder than on the supply. Therefore, problems of boiling and constant sounds are eliminated;

It also happens that two tanks are installed: one on the feed, the second on the return. This is in cases where there are pockets for air in the heating system, and the installation of an additional expansion tank on the return path of the coolant solves this problem.

On the forums there is an opinion that in the installation scheme of the expansion tank on the return closed system heating pumps must be present. There are also refutations to this, in particular, the personal experience of the author who successfully operates such a system without a pump for more than twenty years.

Tank tuning and repair

In this section, we will talk more about repairing sealed expansion heating tanks, since with an iron open tank everything is quite simple. If there is a leak, you need to weld the patch, if it has rotted, and they often rot - a replacement. To configure, you need to fill it in a third. Everything, the tank is ready to go.

Repair of the expansion tank for heating is possible only if it is collapsible, if not, then only the setting. To cover both of these aspects, let's figure out how to replace a torn membrane. To repair and adjust the membrane tank you need:

- remove it by first closing the shut-off valve;

- drain water from it and let the air out of the air chamber through the nipple. If you have the tank installed correctly and the American is behind the tap, a small tank for drained water is enough. If mistakes were made in the sequence of valves and fittings, then prepare for the fact that there will be a lot of water;

- unscrew the bolts on the flange, in which there is a hole for the coolant;

- remove the flange and get the torn rubber bulb (membrane);

- replace the membrane and screw the flange back;

- through the nipple on the back of the tank with an ordinary pump, one and a half atmospheres are pumped;

- put the tank in place and check.

If everything is done correctly, the pressure in the heating system will be stable, without drops. Summing up, it can be noted that in a closed system, a tank cannot be installed immediately after the pump. The nipple of the sealed tank should look down and it is better to install the tank on the return.

In the heating system, an expansion tank for heating is a very important element. Such a device serves to receive excess coolant at the moment when it expands, thus preventing the rupture of the pipeline and taps.

Expansion tank for heating

The principle of operation of the expansion tank for heating is as follows: when the temperature of the coolant rises by 10 degrees, then its volume increases by about 0.3%. Since the liquid is not burned, excessive pressure appears, which must be compensated. It is for this that an expansion tank is installed.

Types of expansion tanks

Different heating systems use different types of expansion tanks. Previously, systems that did not have circulation pumps used an open expansion tank for heating. But such tanks had many drawbacks, so they are currently used very rarely. Due to the fact that air enters into such an expansion tank for heating, corrosion appears, and also the liquid evaporates faster and needs to be constantly replenished. Such a tank should be placed at the highest point of the heating system, and this can not always be easily and simply implemented.

Open expansion tank for heating

In such heating systems, where the heat carrier circulates through a pump, a closed expansion tank for heating is installed, the calculation here is that it is a sealed container that has an elastic membrane inside. The membrane (balloon or diaphragm) divides the tank into two parts. In one part, air or inert gas is injected under pressure, and the other part is for excess coolant. The membrane inside the tank is elastic, so when the coolant enters there, the volume of the air chamber becomes smaller, the pressure in it increases, thereby compensating for the high pressure in the heating system. When cooling, the reverse process takes place.

Installation of closed expansion tanks

A closed expansion tank for heating a flat tank can be flanged (have a replaceable membrane) and with a non-replaceable membrane. The second type is in great demand due to the relatively low cost. But the flange expansion tanks are much better - the pressure here may be greater, and if the membrane bursts, it can be replaced.

The flange expansion tank of the heating system can be either vertical or horizontal.

Here, the liquid, when it enters the tank, has no contact with the metal surface, as it is inside the membrane. If the membrane is damaged, it can be replaced through the flange.

Vertical and horizontal flange tanks

Tanks in which a replaceable membrane is not provided, it is fixed rigidly around the entire perimeter. The diaphragm is pressed from the very beginning to the inner surface, since the volume of the expansion tank for heating is completely filled with gas. After that, the pressure in the expansion tank increases, and the fluid goes inside. When the system starts, the pressure can increase sharply, so at that very moment the membrane can be damaged.

Expansion tank selection

The choice of an expansion tank for heating is a responsible matter. At the same time, attention should be paid not only to its type and size, but also to the membrane - the following indicators are important: resistance to the diffusion process, range of operating temperature, durability, and compliance with sanitary requirements.

Today on the market there is a wide range of expansion tanks for the heating system.

In addition, it is necessary to determine the ratio of the boundaries of the pressure range, which is extremely permissible. Before buying a tank, it is necessary to clarify whether it complies with existing quality and safety standards.

Tank volume calculation

First of all, we determine the dependence of the required volume and the parameters that affect it. When calculating, it must be taken into account that the greater the capacity of the heating system and the higher the maximum temperature of the heat carrier in it, the larger the tank. The higher the permissible pressure in the expansion tank, the less it can be. Of course, the calculation method is quite complicated, so it is better to consult a specialist. After all, a mistake in choosing an expansion tank can cause frequent operation of the safety valve or other troubles.

The calculation of the volume is made according to a special formula. Here, the main value is the total amount of coolant that is present in the heating system. This value is calculated taking into account the boiler capacity, the number and types of heating devices. Approximate values: radiator - 10.5 l / kW, underfloor heating system - 17 l / kW, convector - 7 l / kW.

To make a more accurate calculation of a device such as a vacuum expander for heating, the formula is applied: Tank volume \u003d (Heating system water volume * Heat carrier expansion coefficient) / Expansion tank efficiency. The expansion coefficient for water is 4% when it is heated to 95 degrees. To determine the efficiency of the tank, another formula is used: Tank efficiency \u003d (The highest pressure in the system - Initial pressure in the air chamber) / (The highest pressure in the system + 1).

Expansion tank net volume ratios

Thus, the vacuum expansion tank is selected taking into account the characteristics of strength and temperature, which should not be higher than the permissible values \u200b\u200bat the connection point. The tank volume can either equal or be greater than the result that resulted from the calculations.

Expansion tank installation

Installation of the expansion tank of the heating system is done in accordance with the project and instructions. The best option for you would be for a specialist to do this. If this is not possible, then at least consult with him. Installation of an expansion tank for heating, if it is open type, is carried out at the highest point of the heating system. Closed tank can be placed almost anywhere, but not directly after the pump.

One of the options for installing an expansion tank in the heating system

Particular attention should be paid to such a issue as mounting an expansion heating tank, since the mass of the tank, which is filled with water, increases significantly. Also an important point is the ability and convenience of the tank maintenance, free access to it.

Expansion Tank Service

The role of such a device as the expansion tank of the heating system cannot be understated; the instruction of this device provides a list of the rules for its maintenance. These include:

- Once every six months, it is necessary to check the tank for external damage - corrosion, dents, smudges. If suddenly such damage is found, then be sure to eliminate their cause.

- Once every six months, it is necessary to check the initial pressure of the gas space for compliance with the calculated indicator.

- Once every six months, the integrity of the membrane is checked. If a violation is found, replace it (if this is possible).

- If the tank will not be used for a long time, then you need to keep it in a dry place, draining water from it.

Further, how to check the expansion tank of heating - its initial pressure of the gas space. To do this, disconnect the tank from the heating system, drain water from it, connect a pressure gauge to the nipple of the gas cavity. If the pressure is lower than that which was set at the same time when the expansion tank was adjusted for heating, the tank must be inflated with the compressor through the same nipple.

Pressure gauge readings for correct operation of the expansion tank

Checking the integrity of the membrane is also an important point. If suddenly during checking the pressure of the gas space after you drained the water, air flows through the drain valve, and the pressure in the gas cavity decreases to atmospheric pressure, then the membrane is broken.

To replace the membrane, you need to go through several steps. First of all, the tank is disconnected from the heating system, then it needs to be drained. Further, the pressure of the gas cavity is discharged through the nipple. The flange of the membrane is dismantled. It is located in the area of \u200b\u200bthe pipe for connection with pipes. The membrane included in the expansion tank device for heating is removed from the opening at the bottom of the housing.

Then you need to check the inside of the case so that there are no contaminants and corrosion, if they are, you need to remove them and rinse with water, then dry. To remove corrosion, do not use products that include oils! The membrane holder is inserted into the hole at the top of the membrane. The bolt is screwed into the membrane holder, it is placed in the housing, and the holder is diverted into the hole in the bottom of the housing. Then the holder is fixed with a nut. After that, a membrane flange is placed on the housing.

The best material for car trim

Principles of hardening the body

Do-it-yourself compressor - with minimal scrap costs

Which is better: do-it-yourself or factory-made compressor for painting a car

Causes of fuel pump malfunctions