Protection of the atmosphere

In order to protect the atmosphere from pollution, the following environmental protection measures are applied:

- greening of technological processes;

- cleaning of gas emissions from harmful impurities;

- dispersion of gas emissions in the atmosphere;

- compliance with the standards of permissible emissions of harmful substances;

- arrangement of sanitary protection zones, architectural and planning solutions, etc.

Greening technological processes - this is, first of all, the creation of closed technological cycles, waste-free and low-waste technologies, excluding the ingress of harmful pollutants into the atmosphere. In addition, it is necessary to pre-filter the fuel or replace it with more environmentally friendly types, the use of hydro-dusting, gas recirculation, the conversion of various units to electricity, etc.

The most urgent task of our time is to reduce air pollution with exhaust gases from cars. At present, an active search is under way for an alternative, more "environmentally friendly" fuel than gasoline. The development of car engines running on electricity, solar energy, alcohol, hydrogen, etc.

Purification of gas emissions from harmful impurities. The current level of technology does not allow achieving a complete prevention of the entry of harmful impurities into the atmosphere with gas emissions. Therefore, various methods of cleaning exhaust gases from aerosols (dust) and toxic gaseous and vaporous impurities (NO, NO2, SO2, SO3, etc.) are widely used.

Various types of devices are used to clean emissions from aerosols, depending on the degree of dustiness in the air, the size of solid particles and the required level of cleaning: dry dust collectors (cyclones, dust collection chambers), wet dust collectors (scrubbers, etc.), filters, electrostatic precipitators (catalytic, absorption, adsorption) and other methods for cleaning gases from toxic gaseous and vaporous impurities.

Dispersion of gaseous impurities in the atmosphere - it is a reduction of their hazardous concentrations to the level of the corresponding maximum permissible concentration by dispersing dust and gas emissions using high chimneys. The higher the pipe, the greater its scattering effect. Unfortunately, this method allows to reduce local pollution, but at the same time regional pollution is manifested.

Arrangement of sanitary protection zones and architectural planning measures.

Sanitary protection zone (SPZ) - this is a strip separating sources of industrial pollution from residential or public buildings to protect the population from the influence of harmful production factors. The width of these zones ranges from 50 to 1000 m, depending on the class of production, the degree of hazard and the amount of substances emitted into the atmosphere. At the same time, citizens, whose dwelling was within the SPZ, defending their constitutional right to a favorable environment, can demand either the termination of the environmentally hazardous activity of the enterprise, or resettlement at the expense of the enterprise outside the SPZ.

LECTURE 14.

MEASURES AND MEASURES FOR PROTECTING THE ATMOSPHERIC AIR FROM POLLUTION

Lecture plan:

The main ways to protect the atmosphere from industrial pollution.

Treatment of technological and ventilation emissions. Cleaning off gases from aerosols.

1. The main ways to protect the atmosphere from industrial pollution.

Environmental protection is a complex problem that requires the efforts of scientists and engineers in many specialties. The most active form of environmental protection is:

Creation of waste-free and low-waste technologies;

Improvement of technological processes and development of new equipment with a lower level of emissions of impurities and waste into the environment;

Environmental expertise of all types of industries and industrial products;

Replacement of toxic waste with non-toxic;

Replacement of non-recyclable waste with recycled waste;

Widespread use of additional methods and means of environmental protection.

The following are used as additional means of protecting the environment:

devices and systems for cleaning gas emissions from impurities;

removal of industrial enterprises from large cities to sparsely populated areas with unsuitable and unsuitable for agriculture lands;

optimal location of industrial enterprises, taking into account the topography of the area and the wind rose;

the establishment of sanitary protection zones around industrial enterprises;

rational planning of urban development that provides optimal conditions for humans and plants;

organization of traffic in order to reduce the emission of toxic substances in residential areas;

organization of environmental quality control.

Sites for the construction of industrial enterprises and residential areas should be selected taking into account the aeroclimatic characteristics and terrain.

The industrial facility should be located on a level, elevated place, well-blown by winds.

The residential area should not be higher than the site of the enterprise, otherwise the advantage of tall pipes for dispersing industrial emissions is practically nullified.

The relative position of enterprises and settlements is determined by the average wind rose of the warm season. Industrial facilities that are sources of emissions of harmful substances into the atmosphere are located outside of settlements and on the leeward side of residential areas.

The requirements of the "Sanitary Standards for the Design of Industrial Enterprises SN-245-71" stipulate that facilities that are sources of emission of harmful and unpleasant-smelling substances should be separated from residential buildings by sanitary protection zones. The sizes of these zones are set depending on:

enterprise capacity;

conditions for the implementation of the technological process;

the nature and amount of harmful and unpleasant smelling substances released into the environment.

There are five sizes of sanitary protection zones: for class I enterprises 1000 m, class II 500 m, class III 300 m, class IV 100 m, class V 50 m.

In terms of environmental impact, machine-building enterprises mainly belong to IV and V classes.

The sanitary protection zone can be increased, but not more than threefold by the decision of the Main Sanitary and Epidemiological Directorate of the Ministry of Health of Russia and the Gosstroy of Russia in the presence of unfavorable aerological conditions for dispersing industrial emissions in the atmosphere or in the absence or insufficient efficiency of treatment facilities.

The size of the sanitary protection zone can be reduced by changing technology, improving the technological process and introducing highly efficient and reliable cleaning devices.

The sanitary protection zone may not be used to expand the industrial site.

It is allowed to place objects of a lower hazard class than the main production, fire station, garages, warehouses, office buildings, research laboratories, parking lots, etc.

The sanitary protection zone should be landscaped and landscaped with gas-resistant species of trees and shrubs. From the side of the residential area, the width of green spaces should be at least 50 m, and with a zone width of up to 100 m 20 m.

2. Treatment of technological and ventilation emissions. Cleaning off gases from aerosols.

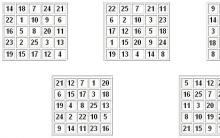

The process of cleaning gases from solid and droplet impurities in various devices is characterized by several parameters, including the overall cleaning efficiency:

If cleaning is carried out in a system of series-connected devices, then the cleaning efficiency:

\u003d 1 (1 1) (1 2)… (1 n).

E  fractional purification efficiency:

fractional purification efficiency:

D  to assess the efficiency of the process, the coefficient of throughput K of particles through the filter is used:

to assess the efficiency of the process, the coefficient of throughput K of particles through the filter is used:

Specific dust capacity of the dust collector:

The amount of dust that it retains during the period of continuous operation between two successive regenerations. The specific dust holding capacity is used to calculate the duration of the filter operation between regenerations.

The efficiency of dust collection depends on the physicochemical properties of dust and mists:

dispersed composition;

density;

adhesion properties;

wettability;

electrical charge of particles;

resistivity of particle layers.

For the correct choice of a dust collecting apparatus, first of all, information on the dispersed composition of dust and fog is required.

Dust fineness is classified into five groups:

I very coarsely dispersed dust, d 50\u003e 140 μm.

II coarse-dispersed dust, d 50 \u003d 40-140 microns.

III medium-sized dust, d 50 \u003d 10-40 microns.

IV fine dust, d 50 \u003d 1-10 microns.

V very fine dust, d 50< 1 мкм.

Adhesion properties ность the tendency of dust particles to stick together. The finer the dust, the higher its stickiness.

The wettability of particles by liquid (water) affects the operation of wet dust collectors.

Cleaning of gases in dry dust collectors.

Dry mechanical dust collectors include devices that use various deposition mechanisms: gravitational, inertial and centrifugal.

Apparatuses using these principles are easy to manufacture and operate, they are widely used in industry. However, the collection efficiency in them is not always sufficient, and therefore they often perform the role of devices for preliminary gas cleaning.

Cyclones... Cyclones are the most common in industry.

Advantages:

a) the absence of moving parts in the apparatus;

b) reliability of work at t up to 500 ° С;

c) the ability to trap abrasive particles while protecting the internal parts with special coatings;

d) trapping dust in dry form;

e) successful work at high gas pressures;

f) ease of manufacture;

h) maintaining high cleaning efficiency while increasing the dust content of the gas.

Disadvantages:

a) high hydraulic resistance;

b) poor collection of particles less than 5 microns;

c) impossibility to use for cleaning gases from sticky contaminants.

Vortex dust collectors... The main difference between vortex dust collectors and cyclones is the presence of an auxiliary swirling gas flow. A distinctive feature of the WPU is the efficiency of gas cleaning from the finest fractions (< 3-5 мкм).

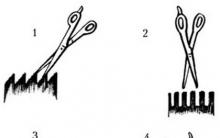

Cleaning gases in filters.

Filters are widely used for fine cleaning of gas emissions from aerosols. The operation of all types of porous filters is based on the process of gas filtration through a porous partition, during which solid particles are retained, and the gas passes completely through it. Filtering partitions are very diverse in their structure and are conventionally divided into the following types:

flexible porous partitions fabric materials made from natural, synthetic or mineral fibers; non-woven fibrous materials (felts, glued and needle-punched materials, paper, cardboard, fibrous sheets); cellular sheets (spongy rubber, polyurethane foam, membrane filters);

semi-rigid porous partitions a layer of fibers, shavings, knitted nets, located on support devices or sandwiched between them;

rigid porous partitions granular materials (porous ceramics or plastic, sintered or pressed metal powders, porous glasses, carbon-graphite materials); metal meshes and perforated sheets.

Filters are divided depending on the purpose and value of the input and output concentration:

Fine filters are designed to capture with very high efficiency (\u003e 99) submicron particles from industrial gases (with C<1 мг/м 3) и скоростью фильтрования <100 м/с. Применяются для улавливания токсичных частиц. Эти фильтры не подвергаются регенерации.

Air filters are used in supply ventilation and air condensation systems. Work at C<50 мг/м 3 , при V=2,5-3,0 м/с; они могут быть регенерируемыми или нерегенерируемыми.

Industrial filters (fabric, granular, coarse-fiber) are used to clean industrial gases with a concentration of up to 60 g / m 3. Filters are regenerated.

Fabric filters... These filters are the most common. The possibilities of their use are expanding in connection with the creation of new temperature-resistant and resistant to aggressive gases tissues. The most widespread are bag filters.

Fine fiber filtersare used in nuclear power engineering, radio electronics, precision instrument making, industrial microbiology and other industries. Filters allow cleaning large volumes of gases from solid particles of all sizes, including submicron ones. They are widely used for the purification of radioactive aerosols. For 99% purification (for particles 0.05-0.5 microns), materials are used in the form of thin sheets or bulk layers of thin or ultra-thin fibers (d< 2 мкм). Скорость фильтрации 0,01-0,15 м/с.

In Russia, filter materials such as FP (Petryanov filters) made of polymer filaments are widely used. Perchlorovinyl (FPP) and cellulose diacetate (FPA) are used as the polymer.

Two-stage or combined filters. In one case, coarse filters from a layer of mylar threads d \u003d 100 microns and fine filters from FP material.

Grain filters. Distinguish between packed and rigid granular filters.

Packed (bulk) filters. In bulk filters, sand, pebbles, slag, crushed rocks, sawdust, coke, rubber chips, plastics, graphite are used as packing. The filters have a nozzle with a grain size of 0.2-2 mm.

Granular harsh filters. In these filters, the grains are firmly bound to each other by sintering, pressing or gluing and form a solid stationary system. These include porous ceramics, porous metals, porous plastics. These filters are used to clean compressed gases.

Cleaning of gases in wet dust collectors.

Wet filters have a number of advantages and disadvantages over other devices.

Advantages:

a) low cost and higher efficiency of collecting suspended particles;

b) the possibility of using for cleaning gases from particles up to 0.1 microns;

c) the possibility of cleaning gases at high temperatures and high humidity, as well as with the danger of fire and explosions of cleaned gases and trapped dust;

d) the ability to trap vapor and gaseous components along with dust.

Disadvantages:

a) the release of captured dust in the form of sludge, which is associated with the need to treat wastewater, which increases the cost of the process;

b) the possibility of entrainment of liquid droplets and their deposition with dust in gas ducts and smoke exhausters;

c) in the case of cleaning aggressive gases, it is necessary to protect equipment and communications with anti-corrosion materials.

In wet dust collectors, water is most often used as the irrigation liquid. Depending on the contact surface or according to the mode of action, they are divided into 7 types:

hollow scrubbers;

packed scrubbers;

disc (bubble, foam) scrubbers;

scrubbers with a movable nozzle;

shock-inertial gas scrubbers;

centrifugal scrubbers;

mechanical gas washers.

Hollow scrubbers. They are the most common. According to the direction of movement of gas and liquid, they are subdivided into counter-flow, direct-flow and with a transverse liquid supply. When working without droplet eliminators V \u003d 0.6-l, 2 m / s; with drop catchers 5-8 m / s. Provides high cleaning for dust particles with a size of 10 microns and is ineffective at d h<5 мкм.

Packed gas scrubbers. They are used to trap well-wetted dust, but at a low concentration. Due to the frequent clogging, such washers are not used much. The liquid flow rate is 0.15-0.5 l / m 3 of gas, the efficiency in capturing particles\u003e 2 microns exceeds 90%.

Gas scrubbers with movable nozzle... They are widely used in dust collection. Balls made of polymeric materials, glass or porous rubber are used as nozzles. The density of the balls of the nozzle should not exceed the density of the liquid.

To ensure a high degree of dust collection, the following process parameters are recommended: W \u003d 5-6 m / s; specific irrigation 0.5-0.7 l / m 3; free cross-section of the plate 0.4 m 2 / m 2 with a slot width of 4-6 mm. The size of the balls is 20-40 mm.

Conical scrubbers with a movable ball head. Two types nozzle and ejection. The apparatus uses polyethylene balls 35-40 mm with a bulk density of 110-120 kg / m 3. The height of the layer of balls is 650 mm, W g.in. \u003d 6-10 m / s, W g.out. \u003d 1-2 m / s, H K \u003d 1 m, \u003d 10-b0 °, Q \u003d from 3000 to 40,000 m 3 / h.

Disc-type scrubbers (bubble, foam)... The most common foam machines are with flop or overflow trays. Overflow trays have holes 3-8 mm and a free section of 0.15-0.25 m 2 / m 2.

Failure plates can be perforated, slotted, tubular, grate. Hole plates have holes 4-8 mm. The width of the slots in other designs is 4-5 mm. Free section 0.2-0.3 m 2 / m 2. Dust is trapped in a foam layer that forms when gas and liquid interact. Modern bubbling and foam devices ensure the efficiency of gas cleaning from fine dust 0.95-0.96 at a specific water consumption of 0.4-0.5 l / m 3.

Shock-inertial gas scrubbers. In these devices, the contact of gases with liquid is carried out due to the impact of the gas flow on the surface of the liquid. As a result of this interaction, droplets of 300-400 microns are formed. The gas velocity is 35-55 m / s, the specific liquid flow rate is 0.13 l / m 3.

Centrifugal gas scrubbers. By design, they are divided into 2 types:

apparatuses in which the swirling of the gas flow takes place with the help of a central blade swirling device;

devices with lateral tangential gas supply.

Most of the domestic centrifugal scrubbers have tangential gas supply and film irrigation. Such devices are used to clean any kind of non-cementing dust.

A centrifugal scrubber TsS-VTI is used to remove ash from flue gases. The specific water consumption is 0.09-0.18 l / m 3.

High-speed gas scrubbers (venturi scrubbers) ... The main part of the apparatus is a spray pipe, in which intensive crushing of the irrigating liquid is ensured by a gas flow moving at a speed of 40-150 m / s. There is a drop catcher.

The cleaning efficiency is 0.96-0.98 for particles with an average size of 1-2 microns at an initial dust concentration of up to 100 g / m 3. Specific water consumption 0.1-6.0 l / m 3. Gas capacity up to 85000 m 3 / h. Venturi scrubbers are widely used in gas mist removal systems. The efficiency of air purification from fog with an average particle size of 0.3 microns reaches 0.999, which is quite comparable with high-efficiency filters.

Mist eliminators... To purify the air from mists of acids, alkalis, oils and other liquids, fibrous filters are used, the principle of which is based on the deposition of droplets on the surface of the pores, followed by the fluid flowing out under the influence of gravity.

Mist eliminators are divided into low-speed (W f 0.15 m / s) and high-speed (W f \u003d 2-2.5 m / s), where sedimentation occurs under the action of inertial forces.

Fibrous low-speed mist eliminators provide high efficiency (up to 0.999) of gas cleaning from particles less than 3 microns in size and completely capture larger particles. Fibrous layers are formed by packing fiberglass with a diameter of 7 to 30 microns or polymer fibers (lavsan, polypropylene) with a diameter of 12 to 40 microns. The layer thickness is 5-15 mm. The hydraulic resistance of dry filter elements is 200-1000 Pa.

High-speed mist eliminators have smaller overall dimensions and provide cleaning efficiency equal to 0.9-0.98 at Р \u003d 1500-2000 Pa, from fog with particles less than 3 microns. Felts made of polypropylene fibers are used as a filtering pad, which work successfully in an environment of dilute and concentrated acids (H 2 SO 4, HCl, HF, H 3 PO 4, HNO 3) and strong alkalis.

Fiber filters of the FVG-T type are used to clean the aspiration air of chrome plating baths containing fog and splashes of chromic and sulfuric acids. The housing contains a cassette with a filtering material needle-punched felt (TU 17-14-77-79), consisting of fibers 70 µm, layer thickness 4-5 mm. Pressure drop 0.15-0.5 kPa, Q \u003d 3500-80000 m 3 / h, cleaning efficiency 0.96-0.99, t90 ° C.

Gas cleaning in electrostatic precipitators. In electrostatic precipitators, dust removal from gases occurs under the action of electrical forces.

The most common electrostatic precipitators are with plate and tubular electrodes. In plate electrostatic precipitators, corona wires are stretched between the collecting plate electrodes. In tubular electrostatic precipitators, the collecting electrodes are cylinders (tubes), inside which the discharge electrodes are located along the axis.

Electrostatic precipitators clean large volumes of gases from dust with particles ranging in size from 0.01 to 100 microns at t \u003d 450 ° C, P \u003d 150 Pa. Specific electricity consumption is 0.36-1.8 MJ per 1000 m 3 of gas. Efficiency 0.999.

Purification of technological and ventilation emissions from gaseous and vaporous pollutants

The processes of purification and neutralization of technological and ventilation emissions from machine-building enterprises from gaseous and vaporous impurities are characterized by the fact that, firstly, the gases emitted into the atmosphere are very diverse in chemical composition; secondly, they sometimes have a high temperature and contain a large amount of dust, which significantly complicates the gas cleaning process and requires preliminary preparation of exhaust gases; third, the concentration of gaseous and vaporous impurities is more often in ventilation and less often in technological emissions, usually variable and low.

Gas cleaning plants created in industry allow to neutralize technological and ventilation emissions without or with subsequent disposal of the captured impurities. Devices with the separation of the product in a concentrated form and its further use in the production cycle are the most promising. The production of such plants is the most important stage in the development of low-waste and zero-waste technology.

Methods for cleaning industrial emissions from gaseous pollutants by the nature of the course of physical and chemical processes are divided into five groups:

physical absorption;

chemisorption;

absorption of gaseous impurities by solid sorbents (adsorption);

thermal neutralization of waste gases;

catalytic cleaning of off-gases.

Absorption method. In flue gas treatment technology, the absorption process is often referred to as a scrubber process. Purification of gas emissions by the absorption method consists in separating the gas-air mixture into its constituent parts by absorbing one or more gas components (absorbates) of this mixture by liquid absorbers (absorbents) with the formation of solutions.

The driving force here is the concentration gradient at the gas-liquid interface. The component of the gas-air mixture (absorber) dissolved in the liquid penetrates into the inner layers of the absorbent due to diffusion. The cleaning process proceeds the faster, the larger the interface, flow turbulence and diffusion coefficients. Therefore, in the process of designing absorbers, special attention should be paid to organizing the contact of the gas stream with a liquid solvent and the choice of an absorbing liquid (absorbent).

The decisive condition when choosing an absorbent is the solubility of the extracted component in it and its dependence on temperature and pressure.

Water is used as an absorbent for physical absorption (to absorb gases such as NH 3, HC1, HF, etc.). In some special cases, high-boiling organic solvents are used as an absorbent to trap aromatic hydrocarbons that are poorly soluble in water.

The organization of the contact of the gas flow with the absorbent is carried out either by passing the gas through the packed column, or by spraying a liquid, or by bubbling the gas through the absorbent layer.

Depending on the implemented method of gas-liquid contact, there are:

a) packed columns;

b) hollow spraying columns;

c) Venturi scrubbers;

d) bubble disc columns.

Geometric bodies of various shapes are used as packing, each of which is characterized by its own specific surface area and resistance to gas flow (Raschig rings, Berl saddles, Pall rings, Intalox saddles). Material: ceramics, porcelain, plastics, metal.

Method chemisorption. It is based on the absorption of gases and vapors by liquid absorbers with the formation of low-volatile or poorly soluble chemical compounds. The absorption capacity of the chemisorbent is almost independent of pressure, therefore, chemisorption is more advantageous with a low concentration of harmful impurities in the exhaust gases. Most of the reactions occurring in the process of chemisorption are exothermic and reversible; therefore, with an increase in the temperature of the solution, the resulting chemical compounds decompose with the release of the initial elements. The mechanism of desorption of the chemisorbent is based on this principle.

An example of chemisorption is the purification of a gas-air mixture from hydrogen sulfide and carbon dioxide using arsenic-alkaline, ethanolamine and other solutions.

Chemisorption is one of the most common ways to remove nitrogen oxides from waste gases. To purify gases from nitrogen oxides escaping from the etching baths, a Venturi scrubber with a nozzle spray of gases with a lime solution is used. The gases from the pickling baths, containing nitrogen oxides, vapors of sulfuric, hydrochloric and hydrofluoric acids, are sent to the scrubber, where they come into contact with the lime solution and are neutralized. The efficiency of purification from nitrogen oxides 0.17-0.86 and from acid vapors 0.95.

Copper-ammonia solutions are used to remove carbon monoxide from exhaust gases.

Method adsorption based on the physical properties of some solids with a developed pore surface to selectively extract and concentrate on their surface individual components from a gas mixture.

Adsorption is divided into physical and chemisorption. In physical adsorption, gas molecules are adsorbed on the surface of a solid under the action of intermolecular attractive forces. The advantage of physical adsorption is the reversibility of the process.

Chemisorption is based on the chemical interaction between the adsorbent and the adsorbed substance. The chemisorption process is usually irreversible.

Substances with a large surface area per unit mass are used as adsorbents or absorbents. Activated carbon and simple and complex oxides (activated alumina, silica gel, activated alumina, synthetic zeolites or molecular sieves) are used as adsorbents. One of the main parameters when choosing an adsorbent is the adsorption capacity for the extracted component.

Structurally, apparatuses for carrying out the adsorption process (adsorber) are made in the form of vertical, horizontal, or annular containers filled with a porous adsorbent, through which the stream of the purified gas is filtered.

Adsorption is widely used in the purification of gas emissions from vapors of organic solvents to remove toxic components (hydrogen sulfide) from gas streams released into the atmosphere, to remove radioactive gases during the operation of nuclear reactors, in particular, radioactive iodine, and in other processes of air purification from harmful impurities.

Thermal neutralization. The method is based on the ability of flammable toxic components (gases, vapors and strong smelling substances) to oxidize to less toxic in the presence of free oxygen and high temperature of the gas mixture. This method is used in cases where the volumes of emissions are high and the concentration of pollutants exceeds 300 ppm.

Thermal neutralization methods for harmful impurities in many cases have advantages over absorption and adsorption:

a) no sludge facilities;

b) small dimensions of treatment plants;

Air is a natural mixture of gases

At the word "air" most of us involuntarily come to mind, perhaps a somewhat naive comparison: air is what we breathe. Indeed, the etymological dictionary of the Russian language indicates that the word "air" is borrowed from the Church Slavonic language: "sigh". From a biological point of view, air is therefore a medium for sustaining life through oxygen. The air might not contain oxygen - life would still develop in anaerobic forms. But the complete absence of air, apparently, excludes the possibility of the existence of any organisms.

For physicists, air is primarily the earth's atmosphere and the gaseous envelope that surrounds the earth.

And what is the air itself from the point of view of chemistry?

Scientists took a lot of effort, work and patience to reveal this mystery of nature, that air is not an independent substance, as it was believed more than 200 years ago, but is a complex mixture of gases. For the first time, the scientist - artist Leonardo da Vinci (15th century) spoke about the complex composition of the air.

About 4 billion years ago, the Earth's atmosphere was composed primarily of carbon dioxide. Gradually, it dissolved in water, reacted with rocks, forming calcium and magnesium carbonates and bicarbonates. With the advent of green plants, this process began to proceed much faster. By the time man appeared, carbon dioxide, so necessary for plants, had already become a deficit. Its concentration in the air before the industrial revolution was only 0.029%. Over the course of 1.5 billion years, the oxygen content gradually increased.

The chemical composition of the air

|

Components |

||

|

By volume |

By mass |

|

|

Nitrogen ( N 2) |

78,09 |

75,50 |

|

Oxygen (O 2) |

20,95 |

23,10 |

|

Noble gases (He, Ne, Ar, Kr, Xe, Rn, mainly argon) |

0,94 |

|

|

Carbon monoxide (IV) - carbon dioxide |

0,03 |

0,046 |

The quantitative composition of the air was first established by the French scientist Antoine Laurent Lavoisier. Based on the results of his famous 12-day experiment, he concluded that all air as a whole consists of oxygen suitable for breathing and combustion, and nitrogen, a lifeless gas, in proportions of 1/5 and 4/5 of the volume, respectively. He heated metallic mercury in a retort on a brazier for 12 days. The end of the retort was brought under a bell placed in a vessel with mercury. As a result, the level of mercury in the bell rose by about 1/5. On the surface of the mercury in the retort, an orange substance - mercury oxide - was formed. The gas remaining under the bell was not breathable. The scientist proposed to rename "vital air" to "oxygen", because when burned in oxygen, most of the substances turn into acids, and "suffocating air" - into "nitrogen", because it does not support life, it hurts life.

Lavoisier's experience

The qualitative composition of the air can be proved by the following experienceThe main constituent of air for us is oxygen, it is 21% by volume in the air. Oxygen is diluted with a large amount of nitrogen - 78% of the volume of air and a relatively small amount of noble inert gases - about 1%. Variable components are also part of the air - carbon monoxide (IV) or carbon dioxide and water vapor, the amount of which depends on various reasons. These substances enter the atmosphere naturally. During volcanic eruptions, sulfur dioxide, hydrogen sulfide and elemental sulfur enter the atmosphere. Dust storms create dust in the air. Nitrogen oxides are released into the atmosphere during lightning electrical discharges, during which nitrogen and oxygen in the air react with each other, or as a result of the activity of soil bacteria capable of releasing nitrogen oxides from nitrates; forest fires and burning of peatlands contribute to this. The processes of destruction of organic substances are accompanied by the formation of various gaseous sulfur compounds. The water in the air determines its humidity. Other substances have a negative role: they pollute the atmosphere. For example, there is a lot of carbon dioxide in the air of cities devoid of greenery, water vapor - over the surface of the oceans and seas. The air contains small amounts of sulfur (IV) oxide or sulfur dioxide, ammonia, methane, nitric oxide (I) or nitrous oxide, hydrogen. The air is especially saturated with them near industrial enterprises, gas and oil fields or volcanoes. There is another gas in the upper atmosphere - ozone. A variety of dust flies in the air, which we can easily notice when looking from the side at a thin beam of light falling from behind a curtain into a darkened room.

Constant constituents of air gases:

· Oxygen

· Nitrogen

· Inert gases

Variable constituents of air gases:

· Carbon monoxide (IV)

· Ozone

· Others

Output.

1. Air is a natural mixture of gaseous substances, in which each substance has and retains its physical and chemical properties, so the air can be separated.

2. Air is a colorless gaseous solution, density - 1.293 g / l, at temperatures of -190 0 С it turns into a liquid state. Liquid air is a bluish liquid.

3. Living organisms are closely related to air substances, which have a certain effect on them. And at the same time, living organisms affect it, as they perform certain functions: redox - they oxidize, for example, carbohydrates to carbon dioxide and reduce it to carbohydrates; gas - absorb and emit gases.

Thus, living organisms created in the past and maintain the atmosphere of our planet for millions of years.

Air pollution - the introduction into the atmospheric air of new uncharacteristic physical, chemical and biological substances or a change in the natural average long-term concentration of these substances in it.

In the process of photosynthesis, carbon dioxide is removed from the atmosphere, and returns in the processes of respiration and decay. The balance established in the course of the evolution of the planet between these two gases began to be disturbed, especially in the second half of the 20th century, when the influence of man on nature began to increase. So far, nature is coping with disturbances of this balance thanks to the ocean water and its algae. But how long will nature have enough strength?

Scheme. Air pollution

The main air pollutants in Russia

The number of cars is constantly growing, especially in large cities, respectively, the emission of harmful substances into the air is growing. On the conscience of cars 60% of emissions of harmful substances in the city!

Thermal power plants in Russia emit up to 30% of pollutants into the atmosphere, and another 30% is the contribution of industry (ferrous and non-ferrous metallurgy, oil production and oil refining, the chemical industry and the production of building materials). The level of air pollution from natural sources is background ( 31–41%

), it changes little over time ( 59–69%

). At present, the problem of anthropogenic pollution of the atmosphere has acquired a global character. What pollutants, dangerous for all living things, enter the atmosphere? These are cadmium, lead, mercury, arsenic, copper, soot, mercaptans, phenol, chlorine, sulfuric and nitric acids and other substances. We will study some of these substances in the future, find out their physical and chemical properties and talk about the destructive power hidden in them for our health.

The scale of environmental pollution of the planet, Russia

In which countries of the world is the air most polluted by transport exhaust gases?

The greatest danger of atmospheric pollution from exhaust gases threatens countries with a powerful fleet of vehicles. For example, in the United States, motor vehicles account for about 1/2 of all harmful emissions into the atmosphere (up to 50 million tons annually). The vehicle fleet of Western Europe annually emits up to 70 million tons of harmful substances into the air, and in Germany, for example, 30 million cars give 70% of the total volume of harmful emissions. In Russia, the situation is aggravated by the fact that the vehicles in operation comply with environmental standards only by 14.5%.

It pollutes the atmosphere and air transport with exhaust plumes from many thousands of aircraft. According to expert estimates, as a result of the activities of the global vehicle fleet (which is about 500 million engines), 4.5 billion tons of carbon dioxide alone enter the atmosphere annually.

Why are these pollutants dangerous? Heavy metals - lead, cadmium, mercury - have a harmful effect on the human nervous system, carbon monoxide - on the blood composition; Sulfur dioxide, interacting with rain and snow water, turns into acid and causes acid rain. What is the scale of this pollution? The main regions where acid rain is spread are the USA, Western Europe, and Russia. Recently, these include the industrial regions of Japan, China, Brazil, and India. The concept of transboundary is associated with the spread of acid precipitation - the distance between the regions of their formation and the regions of precipitation can be hundreds and even thousands of kilometers. For example, the main culprit for acid rain in southern Scandinavia is the industrial regions of Great Britain, Belgium, the Netherlands and Germany. Acid rain is transported to the Canadian provinces of Ontario and Quebec from neighboring regions of the United States. These precipitations are carried to the territory of Russia from Europe by westerly winds.

An unfavorable ecological situation has developed in the northeast of China, in the Pacific belt of Japan, in the cities of Mexico City, Sao Paulo, Buenos Aires. In Russia in 1993 in 231 cities with a total population of 64 million people, the content of harmful substances in the air exceeded the norm. In 86 cities, 40 million people live in conditions where pollution exceeds the norms by 10 times. Among these cities are Bryansk, Cherepovets, Saratov, Ufa, Chelyabinsk, Omsk, Novosibirsk, Kemerovo, Novokuznetsk, Norilsk, Rostov. In terms of the amount of harmful emissions, the Ural region occupies the first place in Russia. So, in the Sverdlovsk region, the state of the atmosphere does not meet the standards in 20 territories, where 60% of the population lives. In the city of Karabash, Chelyabinsk region, a copper smelter annually emits 9 tons of harmful compounds into the atmosphere for each inhabitant. The incidence of cancer here is 338 cases per 10 thousand inhabitants.

An alarming situation has also developed in the Volga region, in the south of Western Siberia, in Central Russia. In Ulyanovsk, more than the Russian average, people suffer from diseases of the upper respiratory tract. The incidence of lung cancer has increased 20 times since 1970, the city has one of the highest levels of infant mortality in Russia.

A large number of chemical enterprises are concentrated in the city of Dzerzhinsk in a limited area. Over the past 8 years, 60 emissions of potent toxic substances into the atmosphere have occurred here, leading to emergency situations, in a number of cases resulting in the death of people. In the Volga region, up to 300 thousand tons of soot, ash, soot, carbon oxides fall on city residents annually. Moscow ranks 15th among Russian cities in terms of the total level of air pollution.

Have you ever thought about how important air is in our life?

Just imagine that human life cannot go on without him for more than two minutes. We rarely think about this, taking air for granted, however, there is a real problem - the Earth's atmosphere is already quite polluted. And she suffered precisely at the hands of a man. And this means that all life on the planet is in danger, because we constantly inhale various poisonous substances and impurities. How to protect the air from pollution?

How do people and their activities affect the state of the atmosphere?

The faster modern society develops, the more and more needs it has. People need more cars, more appliances, more products for daily use - the list goes on. However, the point is that to meet the needs of modern people, you need to constantly produce and build something.

To do this, forests are rapidly being cut down, new companies are being created, plants and factories are opening, which daily emit tons of chemical waste, soot, gases, and all kinds of harmful substances into the atmosphere. Hundreds of thousands of new cars appear on the roads every year, each of which contributes to the pollution of the atmosphere. People unwisely use resources, minerals, dry up rivers, and all these actions directly or indirectly affect the state of the Earth's atmosphere.

The gradually decaying ozone layer, designed to protect all living things from radioactive solar radiation, is evidence of unreasonable human activity. Its further thinning and destruction will lead to the death of both living organisms and the plant world. How to save the planet from atmospheric pollution?

What are the main sources of air pollution?

Modern car industry... Currently, there are over 1 billion cars on the roads of all countries of the world. In Western and European countries, almost every family has several cars at their disposal. Each of them is a source of exhaust gases that enter the atmosphere in tons. In China, India and Russia, the situation seems to be not the same, but the number of cars in the CIS in comparison with 1991, clearly increased significantly.

Factories and plants... Of course, one cannot do without industry, but we should not forget that when we receive the goods we need, in return we pay with clean air. Soon, mankind will have nothing to breathe if factories and industrial enterprises do not learn to recycle their own waste instead of releasing it into the atmosphere.

The products of combustion of oil and coal consumed at thermal power plants rise into the air, filling it with very harmful impurities. In the future, toxic waste falls out along with precipitation, feeding the soil with chemicals. Because of this, green spaces are dying, and in fact they are necessary to absorb carbon dioxide and produce oxygen. And what about us without oxygen? Let's die ... So air pollution and human health are in direct proportion.

Air pollution protection measures

What measures can humanity take to stop polluting the planet? Scientists have known the answer to this question for a long time, but in fact, few are implementing these measures. What should be done?

1. Officials should strengthen control over the organization of safe for nature and environment work of factories and industrial enterprises. It is necessary to oblige the owners of all plants to install treatment facilities in order to reduce harmful emissions to the atmosphere to zero. Penalties may be imposed for violations of these obligations, possibly in the form of a ban on the continuation of activities of enterprises that continue to pollute the air.

2. To produce new cars that would run only on environmentally friendly fuels. If we stop the production of cars that consume gasoline and diesel fuel as fuel, and replace them with electric vehicles or hybrid cars, then buyers will have no choice. People will buy cars that do not harm the atmosphere. Over time, there will be a complete replacement of old cars with new, environmentally friendly ones, which will greatly benefit us, the inhabitants of the planet. Already now, many people living in the countries of the European continent make a choice in favor of such transport.

The number of electric vehicles in the world has already reached 1.26 million. According to the forecast of the International Energy Association, in order to prevent a rise in temperature due to warming of more than 2 degrees, it is necessary to increase the number of electric vehicles on the roads to 150 million by 2030 and 1 billion by 2050, among others. available production figures.

3. Environmentalists agree that if the operation of outdated thermal power plants is stopped, the situation will stabilize. However, first it is necessary to find and introduce new ways of extracting energy resources. Many of them have already been used successfully. People have learned to convert the energy of the sun, water and wind into electricity. Alternative types of energy resources are not associated with the release of hazardous waste into the environment, which means they will help protect the air from pollution. In reality, more than half of the electricity in Hong Kong comes from coal-fired thermal power plants, and therefore the share of carbon dioxide emissions in recent years has increased by 20%.

4. In order for the ecological situation to stabilize, it is necessary to stop destroying natural resources - to cut down forests, drain water bodies and start wisely using minerals. It is necessary to constantly increase the green spaces so that they help purify the air and enrich it with oxygen.

5. It is necessary to raise public awareness. In particular, information on how to protect the air from pollution for children. Thus, you can change the approach of many people to the current state of the situation.

Air pollution raises many new problems - the incidence of cancer is increasing, the life expectancy of people is decreasing, but this is just the tip of the iceberg. The real trouble is that the spoiled ecology threatens global warming, and this will lead to serious natural disasters in the future. Already now, the protest of our planet against the thoughtless activities of people is manifested in the form of floods, tsunamis, earthquakes and other natural phenomena. Humanity needs to seriously think about how to protect the air from dirt.

Air basin protection is one of the most pressing environmental problems. The protection of the atmosphere from pollution by industrial and transport emissions is the most important social task included in the complex of tasks of the global problem of nature protection and improvement of the use of natural resources. Air pollution with harmful substances causes significant material damage to the national economy and leads to an increase in the morbidity of the population.

Atmospheric protection problems constitute a wide area at the intersection of sciences. It includes both general tasks of chemical technology, power engineering, physics and mechanical engineering, and issues that are addressed by doctors, hygienists, etc.

The most effective method of protecting the atmosphere from pollution by harmful substances is the development of new low-waste resource and energy-saving technological processes with closed production cycles. However, these issues require large financial costs and the development of new modern technologies and materials. Therefore, without postponing the solution of these issues for the future, at the present stage for most industrial and transport enterprises, the purification of air emitted into the atmosphere remains the main measure to protect the air basin from pollution.

From the total mass of air pollutants,

coming from anthropogenic sources, about 90% are gaseous of various kinds, and 10% are solid and liquid substances.

Suspended substances in the air are called aerosols, which are usually divided into three classes: dust, smoke and fog.

Dusts are polydisperse systems of solid suspended particles ranging in size from 5 to 100 microns.

Smokes - aerosols with particle sizes from 0.1 to 5 microns.

Mists are liquid aerosols composed of liquid droplets. They may contain solutes or particulates. They form as a result of condensation of steam or spraying of liquids. The particle size in the first case is close to fumes, and in the second - to dust.

A special place is occupied by soot and ash formed in the process of fuel combustion.

Soot is a toxic, highly dispersed powder containing 95% carbon particles.

Ash - unburned fuel residue, consisting of mineral impurities.

In the technology of dust collection and gas cleaning, the dispersed composition of dust is of decisive importance, since the appropriate dust collection equipment is selected depending on this.

The most typical gaseous air pollution includes:

sulfur dioxide ( SO 2 ),

carbon monoxide ( CO),

nitrogen oxides and dioxides ( NO, NO 2 ),

hydrocarbons (gasoline vapors, methane, etc.),

compounds of heavy metals (lead, mercury, cadmium, etc.),

carbon dioxide ( CO 2).

Naturally, there may be other harmful gaseous substances in the air due to the presence of one or another production nearby. Air emissions are categorized into:

1 - steam-gas and aerosol;

2 - technological and ventilation;

3 - organized and unorganized;

4 - hot and cold.

According to the 1st classification, steam-gas emissions are a mixture of gases that do not contain solid or liquid particles. Aerosol emissions are a mixture of gases that contain solid or liquid particles.

Depending on the harmfulness of the gas components and the aerosol particles contained in them, it is necessary to purify either one component of the mixture, or the mixture as a whole. In the latter case, either combined cleaning in one apparatus is required, or a combination of sequential arrangement of apparatus.

Technological emissions are generated as a result of technological processes and are blowdown emissions, emissions from safety valves, from boiler pipes, vehicles, etc. As a rule, they are characterized by a high concentration of pollutants. Ventilation emissions are characterized by large volumes of air-gas mixture, but low concentrations of pollutants. At the same time, due to the large volumes of the air-gas mixture, the gross emissions of pollutants with them can be significant.

Organized emissions include emissions removed by pipes or flue gas ducts, which makes it possible to use gas and dust collection plants quite easily. Unorganized - emissions from unpressurized equipment, emissions from unequipped places for loading or unloading materials, from transport systems, etc.

Hot or cold emissions are distinguished by the temperature difference between the gas and the environment. With a temperature difference of up to 30 ° C, the emissions can be considered cold.

The operation of any device that removes suspended particles is based on the use of one or more sedimentation mechanisms. The main ones that have the greatest application include: gravitational sedimentation, sedimentation under the action of centrifugal forces, inertial sedimentation, engagement (touch effect), diffusion sedimentation, electrodeposition. Modern methods include thermophoresis and exposure to an electromagnetic field. The influence of one mechanism or another on the deposition of particles is determined by a number of factors, and primarily by their size.

Gravitational settling occurs as a result of the vertical settling of particles by gravity. When a dust particle falls, it experiences the resistance of the environment, therefore the speed of falling or settling is determined by the condition of equality of gravity and hydraulic resistance. Therefore, particles of a smaller diameter will have a lower sedimentation rate and to clean the air from such particles, it will take a longer time for the dusty stream to stay in the dust settling chamber.

Centrifugal deposition of dust is observed during the curvilinear movement of a dusty stream, when, under the action of the developed centrifugal forces, dust particles are thrown onto the deposition surface. In devices based on the use of centrifugal forces, two principal design solutions can be applied. In one case, the dust and gas flow rotates in a stationary body of a cylindrical or conical apparatus. And in the second case, the dust and gas flow moves in a rotating rotor. The first solution is carried out in cyclones and the second in rotary dust collectors.

Inertial deposition occurs when the mass of a dust particle cannot follow with the gas along a streamline enveloping a substance that is dense in comparison with air; by inertia, when the flow turns, continues rectilinear motion. In this case, the dust particle collides with an obstacle and settles on it. Inertial deposition of dust particles is effective for particles larger than 1 micron.

Diffusion deposition will be observed when particles, which are mostly small in size, are subject to Brownian motion

molecules. As a result, they have an increased likelihood of contact with the streamlined body. The efficiency of diffusion deposition is inversely proportional to particle size and gas flow rate.

The deposition of dust particles under the action of an electric current consists in charging the particles with their subsequent separation from the air environment under the action of an electric field. Dust particles can be charged with aerosol generation, free current diffusion and short discharge. In the latter case, dust particles are charged with one sign, which makes it possible to increase the efficiency of their subsequent removal from the air stream.

Thermophoresis is the repulsion of particles by a heated body caused by the movement of air as a result of free convection. During thermophoresis, the concentration of particles in areas with high and low temperatures becomes different, which leads to thermal diffusion of particles towards lower temperatures. In practice, this can be observed in the form of dust settling on the outer walls against central heating appliances.

The deposition of suspended particles upon contact of a gas flow with a liquid can be carried out on drops, bubbles and on the surface of the liquid.

The collection of suspended particles by droplets is based on kinematic coagulation resulting from the difference in the velocities of particles and droplets.

This can happen:

When the aerosol moves at a low speed, and the liquid droplets fall under the action of gravity;

When aerosol and droplets move in the same or opposite directions at different speeds.

When polluted air bubbles move through the liquid layer (bubbling), gas pulsation occurs inside the bubbles. At the same time, suspended particles stick to the surface of the water surrounding the gas bubble.

During the deposition of solid particles on the surface of a liquid, in the case when the gas flow moves along the liquid surface, the particles are deposited in water in the volume of a thin film, i.e. surface water pollution occurs.

Gas filtration through porous materials consists in the passage of aerosol through filter baffles that allow air to pass through, but retain aerosol particles. The filtration process in the most common filters can be conventionally taken as the process of flowing around a cylinder located across the flow. Dust particles are retained on the fiber surface by molecular forces. Filtration of a dust-laden flow through a porous material is much more difficult, since it includes not only the process of adhesion to the material as a result of flow, but also due to collisions with fibers or filaments. It should be borne in mind that there are usually several rows of fibers in the path of the dusty stream, which increases the cleaning efficiency.

When extracting gaseous impurities, the methods of absorption, adsorption, catalysis and thermal oxidation are used.

Absorption cleaning is based on the ability of liquids to dissolve gases or chemically interact with them. During absorption, the substance passes from the gas phase to the liquid. The substance in which the absorbed gas components dissolve is called an absorbent. The remainder of the gas stream that is not absorbed into the liquid is commonly referred to as inert gas. During physical absorption, the absorbable component is physically dissolved in the solvent (absorbent). In this case, chemical reactions do not occur. This process occurs when the partial pressure of the absorbed component in the gas is greater than the equilibrium partial pressure above the surface of the solution.

During chemical absorption (chemisorption), the absorbed component enters into a chemical reaction with the absorber (liquid), forming new chemical compounds in the liquid phase. Chemisorption processes provide a more complete extraction of components from gas mixtures. The amount of gases that can be dissolved in a liquid depends on the properties of the gas and the liquid, the temperature and the partial pressure of the gas above the liquid.

The absorption process is understood as the absorption of a gaseous component by a solid. The phenomenon of adsorption is due to the presence of attractive forces between the molecules of the adsorbent (solid) and the absorbed gas at the interface of the contacting phases. The process of the transition of molecules from a gas to the surface layer of the adsorbent occurs when the forces of attraction of the adsorbent exceed the forces of attraction from the side of the carrier gas. The molecules of the adsorbed substance, passing to the surface of the adsorbent, reduce its energy, resulting in the release of heat.

During physical adsorption, gas molecules do not chemically interact with adsorbent molecules. With an increase in temperature, the amount of physically adsorbed substance decreases, and an increase in pressure leads to an increase in the amount of adsorption. The advantage of physical adsorption is the easy reversibility of the process.

Chemical adsorption is based on the chemical interaction between the adsorbent and the adsorbed substance. The forces acting in this case are much greater than during physical adsorption, and more heat is released at the same time. Gas molecules, having entered into chemical interaction with adsorbent molecules, are firmly held on the surface and in the pores of the adsorbent. It is characteristic that at low temperatures the rate of chemical adsorption is low, but it increases with increasing temperature.

Catalytic gas cleaning is used to convert impurities into harmless compounds. The process takes place on the surface of solid bodies - catalysts. The selection of catalysts is mainly decided empirically.

The catalysis process is greatly influenced by temperature. At relatively low temperatures, when the reaction rate is slow compared to the rate of gas diffusion and the purification process is relatively slow. As the temperature rises, the rate of the chemical reaction increases, while the rate of gas diffusion also increases. However, the diffusion rate increases more slowly and a moment may come when the gas purification process will be determined only by the rate of supply of reactants, and the use for this, as at the initial stage of the process, of the inner surface of the catalyst is close to zero. In this case, catalysis passes into the region of external diffusion. In this case, the small pores of the catalyst no longer play any role, but the role of the outer surface increases.

The most important characteristic of catalysts is the "ignition" temperature - the minimum temperature at which the catalyst begins to show its properties.

Thermal oxidation of emission components is called oxidation at temperatures up to 1000 ° C. Oxidation is used both for gases and combustible components of the dispersed phase of aerosols. This method finds application for the extraction of resins, oils, volatile solvents and other components from gas streams. Preparation of gases for reaction is of decisive importance in organizing the process, i.e. heating the mixture to the required temperature and ensuring the mixing of combustible gases with the oxidizer.

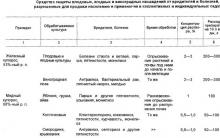

|

Sources of air pollution |

Treatment facilities |

Note |

|

Oil fired boiler room |

Cyclone or cyclone battery Bag filters |

Calculation clause 4.6 Calculation p.4.7 |

|

Gaseous fuel boiler room |

Self-contained suggestions |

Method description |

|

Solid fuel boiler room |

Cyclone battery Bag filters |

Calculation clause 4.6 Calculation p.4.7 |

|

Painting and drying booth |

Adsorber |

Calculation p.4.8 |

|

Welding workshop: welding production |

Venturi scrubber (Gas scrubber KMP) |

Calculation p. 4.3 |

|

Machine shop: machine tool equipment |

Dust chamber Cyclone CN |

Calculation of clause 4.2 |

|

Woodworking workshop |

Dust chamber Cyclone Giprodrevprom |

Calculation of clause 4.2 Calculation clause 4.6 |

|

Electroplating workshop |

Mesh mist eliminator |

Calculation p.4.4 |

What to give a vegetarian for his birthday

Face cream at home - preparation rules

An ancient recipe for youth from Tibetan monks

How to drink clay to cleanse the body

Download maps slavic oracle